Home>Create & Decorate>DIY & Crafts>Pallet Shed Building: A DIY Guide

DIY & Crafts

Pallet Shed Building: A DIY Guide

Published: February 29, 2024

Content Creator specializing in woodworking and interior transformations. Caegan's guides motivate readers to undertake their own projects, while his custom furniture adds a personal touch.

Learn how to build a pallet shed with our comprehensive DIY guide. Get creative with DIY & Crafts and build your own storage space. Start your project today!

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Twigandthistle.com, at no extra cost. Learn more)

Introduction

Building a shed from pallets is a rewarding and cost-effective DIY project that allows you to create a functional and charming outdoor space. Whether you need extra storage, a workshop, or a cozy retreat, a pallet shed can be a versatile addition to your property. This comprehensive guide will walk you through the step-by-step process of constructing a pallet shed, from planning and preparation to the finishing touches.

Constructing a pallet shed is not only a practical endeavor but also an environmentally friendly one. By repurposing pallets, you can reduce waste and contribute to sustainable building practices. Additionally, the rustic and unique aesthetic of a pallet shed adds character to your outdoor area, making it a standout feature in your backyard or garden.

Throughout this guide, you will learn how to select the right pallets, choose an ideal site for your shed, and construct a sturdy foundation. We will delve into the framing and construction process, providing detailed instructions and tips to ensure a successful build. From roofing and siding to the final finishing touches, you will gain valuable insights into each stage of the construction, empowering you to create a durable and visually appealing pallet shed.

Whether you are a seasoned DIY enthusiast or a novice builder, this guide is designed to equip you with the knowledge and confidence to tackle the project. With careful planning and the right tools, you can embark on this fulfilling journey of transforming reclaimed pallets into a functional and charming outdoor structure. Get ready to unleash your creativity, hone your carpentry skills, and embark on an exciting pallet shed building adventure.

Read more: How To Build A Pallet

Planning and Preparation

Before diving into the construction of a pallet shed, thorough planning and preparation are essential for a successful and efficient build. This phase sets the foundation for the entire project, ensuring that you have a clear vision and the necessary resources to bring your pallet shed to life.

Assess Your Needs

Begin by assessing your specific requirements for the shed. Consider its intended use, whether it's for storage, a workshop, or a recreational space. Understanding your needs will help determine the size, layout, and features of the shed, guiding your planning process.

Obtain Permits and Regulations

Check local building codes and regulations to determine if any permits are required for constructing a shed on your property. Compliance with regulations is crucial to avoid potential issues in the future. Additionally, familiarize yourself with any zoning restrictions or covenants that may impact the shed's location and design.

Create a Design and Material List

Sketch a rough design of the pallet shed, incorporating dimensions and layout based on your needs and available space. This design will serve as a blueprint for the construction process. Make a comprehensive list of materials and tools required for the build, ensuring that you have everything on hand before commencing the project.

Gather Quality Pallets

Collecting suitable pallets is a critical aspect of the preparation phase. Look for pallets in good condition, free from rot, mold, or chemical treatments. Ideally, choose pallets of uniform size and shape to facilitate construction. Consider reaching out to local businesses or recycling centers to acquire pallets at minimal or no cost.

Prepare the Building Site

Clear the designated area for the shed, ensuring it is level and free from debris. Take accurate measurements and mark the boundaries of the shed's footprint. This step is crucial for laying the foundation and positioning the pallets during construction.

Arrange Tools and Safety Gear

Gather the necessary tools, such as a circular saw, hammer, nails, screws, and a level, to facilitate the construction process. Additionally, prioritize safety by ensuring you have protective gear, including gloves, safety glasses, and sturdy footwear.

Set a Realistic Timeline

Establish a realistic timeline for the project, considering factors such as weather conditions, your availability, and any assistance you may require. Setting achievable milestones will help you stay organized and motivated throughout the construction process.

By meticulously planning and preparing for the pallet shed build, you lay a solid groundwork for a smooth and rewarding construction journey. With careful consideration of your needs, adherence to regulations, and meticulous preparation, you are poised to embark on the next phase of the project: choosing the right pallets for your shed.

Read more: How to Build a Pallet Bathroom Vanity

Choosing the Right Pallets

Selecting the appropriate pallets is a crucial step in ensuring the structural integrity and aesthetic appeal of your pallet shed. The quality and condition of the pallets directly impact the durability and overall look of the final structure. Here's a detailed exploration of the factors to consider when choosing the right pallets for your project:

Material and Condition

Opt for pallets constructed from sturdy and durable wood, such as oak, maple, or pine, as they offer the strength required for a long-lasting shed. Inspect the pallets for signs of damage, including cracks, splits, or rot. Avoid pallets that show indications of mold, mildew, or chemical spills, as these can compromise the integrity of the shed and pose potential health hazards.

Size and Uniformity

Consistency in pallet size is essential for streamlined construction. Look for pallets with uniform dimensions, as this will simplify the framing and assembly process. Ideally, select pallets of the same size to ensure a cohesive and professional finish. Standard pallet sizes, such as 48" x 40", are commonly used in the industry and offer compatibility with various construction techniques.

Certification and Treatment

When sourcing pallets, prioritize those that bear the International Standard for Phytosanitary Measures (ISPM) 15 mark, indicating that they have been heat-treated or fumigated to prevent pest infestation. Avoid pallets treated with hazardous chemicals, especially if the shed will be used for storage or habitation. Additionally, seek pallets with visible certification stamps, ensuring compliance with safety and quality standards.

Read more: Creative Pallet Bathroom DIY Ideas

Sustainability and Reusability

Embrace the eco-friendly aspect of pallet construction by choosing reclaimed or repurposed pallets. By opting for pallets with a history of use, you contribute to sustainable building practices and reduce the demand for new timber resources. Prioritize pallets that have been responsibly sourced and have the potential for future reuse, aligning with environmentally conscious principles.

Quantity and Accessibility

Assess the quantity of pallets required based on the shed's size and design. Consider factors such as the pallets' load-bearing capacity and their availability for future projects. Ensure that you have access to a sufficient number of pallets to complete the construction, factoring in potential wastage or the need for additional materials during the build.

By carefully evaluating these considerations, you can confidently select the right pallets for your shed, laying the groundwork for a structurally sound and visually appealing final product. The process of choosing the right pallets sets the stage for the subsequent phases of construction, guiding the framing, siding, and finishing touches of your pallet shed.

Site Selection and Foundation

The site selection and foundation phase of building a pallet shed play a pivotal role in ensuring the structural stability and longevity of the structure. Careful consideration of the shed's placement and the establishment of a solid foundation are essential for a successful construction process.

Assessing the Site

Begin by evaluating potential locations for the pallet shed within your property. Consider factors such as sunlight exposure, drainage patterns, and proximity to existing structures. Opt for a site that receives ample natural light and is well-drained to prevent moisture-related issues. Additionally, ensure that the shed's placement complies with local zoning regulations and does not encroach on utility easements or property boundaries.

Read more: DIY Pallet Kitchen Island Guide

Foundation Preparation

Once the site is selected, the next step involves preparing the foundation. Depending on the soil composition and the shed's intended use, you can choose from various foundation options, including concrete piers, gravel pads, or concrete slabs. Clear the area of vegetation and debris, ensuring a level surface for the foundation. Use a string level or a transit to establish a uniform grade, essential for the stability of the shed.

Building a Solid Foundation

For a traditional approach, consider using concrete piers to support the shed's structure. Dig holes at designated intervals and pour concrete into form tubes to create sturdy piers. Alternatively, a gravel pad offers a cost-effective and versatile foundation option. By layering gravel and compacting it to form a stable base, you provide adequate support for the shed while promoting natural drainage.

Anchoring the Pallets

With the foundation in place, anchor the pallets securely to the chosen foundation type. Use concrete anchors or heavy-duty screws to fasten the pallets to the foundation, ensuring they are level and aligned according to the shed's design. This step is crucial for preventing shifting or movement of the shed, especially in areas prone to high winds or seismic activity.

Considerations for Drainage

Incorporate proper drainage measures into the foundation design to mitigate water accumulation around the shed. This can include grading the surrounding soil away from the shed, installing gutters and downspouts, or incorporating a French drain system to redirect excess water. Effective drainage safeguards the shed against moisture-related issues and prolongs its structural integrity.

By meticulously selecting the site and establishing a robust foundation, you set the stage for the subsequent phases of pallet shed construction. The careful attention to site placement and foundation preparation ensures that your pallet shed is built on a solid and enduring base, ready to progress to the framing and construction phase.

Read more: Simple Pallet Garage Shelving Guide

Framing and Construction

The framing and construction phase marks a significant milestone in the journey of building a pallet shed. This stage involves translating the design blueprint into a tangible structure, encompassing the assembly of pallets to form the walls, doors, and windows of the shed. Here's a detailed exploration of the key steps involved in the framing and construction process:

Wall Assembly

Begin by arranging the pallets in a manner that aligns with the shed's design. Secure the pallets together using heavy-duty screws or nails, ensuring a stable and uniform wall structure. To enhance stability, consider reinforcing the corners and junctions with additional bracing or framing. This step forms the foundation of the shed's framework, setting the stage for subsequent construction elements.

Door and Window Openings

If the shed design incorporates doors and windows, carefully measure and mark the locations for these openings on the assembled pallet walls. Use a saw to cut through the pallet boards, creating precise openings for the installation of doors and windows. Pay close attention to accuracy and alignment to facilitate seamless integration of these essential components.

Roof Truss Installation

Constructing the roof trusses is a critical aspect of the framing process. Depending on the shed's size and design, fabricate trusses using additional pallets or structural lumber. Ensure that the trusses are engineered to bear the anticipated roof load and provide adequate support. Position the trusses at designated intervals along the shed's walls, securing them firmly to create a sturdy framework for the roof.

Read more: DIY Pallet Wall Shelf for Bedroom

Structural Reinforcement

As the framing progresses, assess the structural integrity of the shed and reinforce areas that may require additional support. This can involve adding cross-bracing between walls, installing support beams for the roof trusses, and ensuring that the overall framework is resilient and capable of withstanding external forces. Attention to structural reinforcement contributes to the long-term durability of the pallet shed.

Integration of Utility Features

Consider integrating utility features, such as electrical wiring or insulation, into the framework during the construction phase. Plan for the installation of lighting, power outlets, and insulation materials, ensuring that the framework accommodates these elements seamlessly. This proactive approach streamlines the subsequent stages of shed customization and enhances its functionality.

Progress Monitoring and Adjustment

Throughout the framing and construction process, regularly assess the alignment, levelness, and overall quality of the shed's framework. Make necessary adjustments to address any discrepancies and ensure that the construction adheres to the initial design specifications. This meticulous monitoring and adjustment phase contribute to the precision and quality of the final structure.

By meticulously executing the framing and construction phase, you lay the groundwork for a robust and visually appealing pallet shed. The attention to detail, structural integrity, and integration of essential components during this stage set the stage for the subsequent roofing, siding, and finishing touches, bringing your pallet shed closer to completion.

Roofing and Siding

The roofing and siding phase of building a pallet shed is a pivotal stage that culminates in providing weather protection, structural integrity, and aesthetic appeal to the structure. This phase involves the installation of roofing materials to shield the shed from the elements and the application of siding to enhance its visual appeal and durability. Here's a comprehensive exploration of the key steps involved in the roofing and siding process:

Read more: DIY: Building A Lean To Shed

Roofing Installation

Begin by selecting suitable roofing materials that align with the shed's design, climate considerations, and your preferences. Options such as corrugated metal panels, asphalt shingles, or polycarbonate sheets offer varying degrees of durability, insulation, and visual appeal. Ensure that the chosen roofing materials are compatible with the shed's framework and provide adequate protection against rain, snow, and UV exposure.

Lay the roofing materials methodically, starting from the eaves and progressing towards the ridge. Secure the roofing panels or shingles using appropriate fasteners, ensuring a tight fit and weatherproof seal. Pay attention to overlapping joints and flashing details to prevent water infiltration and promote efficient water shedding. Additionally, consider incorporating roof vents or skylights to enhance ventilation and natural light within the shed, contributing to a comfortable and functional interior environment.

Siding Application

Select siding materials that complement the overall aesthetic of the shed while offering durability and protection. Common options include exterior-grade plywood, composite cladding, or reclaimed wood planks. Evaluate the visual impact, maintenance requirements, and weather resistance of each siding material before making a decision.

Install the siding systematically, starting from the bottom and working upwards to facilitate proper water drainage. Secure the siding panels or planks to the shed's framework using weather-resistant screws or nails, ensuring a snug and uniform fit. Pay attention to corner details, window and door surrounds, and trim elements to create a cohesive and visually appealing exterior finish.

Incorporate protective coatings or sealants to enhance the longevity of the siding, safeguarding it against moisture, UV exposure, and fungal growth. Consider painting or staining the siding to add a personalized touch and further fortify its resistance to environmental factors. Additionally, integrate proper flashing and caulking around openings and junctions to create a watertight envelope for the shed.

By meticulously executing the roofing and siding phase, you elevate the functionality, durability, and visual allure of the pallet shed. The careful selection and installation of roofing materials, coupled with the precise application of siding, contribute to the shed's resilience and aesthetic charm, bringing it closer to its completion.

Finishing Touches

With the structural elements in place, the finishing touches phase adds the defining details and personalization to your pallet shed, transforming it from a functional structure to a visually captivating and fully equipped space. This phase encompasses a range of considerations, including interior customization, aesthetic enhancements, and practical additions that elevate the shed's overall appeal and usability.

Interior Customization

Embrace the opportunity to tailor the interior of the pallet shed to suit your specific needs and preferences. Consider installing storage solutions such as shelves, cabinets, or hanging racks to optimize the use of space and keep the interior organized. Incorporate a workbench or a designated area for your hobbies or projects, creating a functional and inviting workspace within the shed. Additionally, explore creative lighting options, such as LED fixtures or solar-powered lamps, to illuminate the interior and enhance its ambiance.

Read more: How To Make A Bar Out Of Pallets

Aesthetic Enhancements

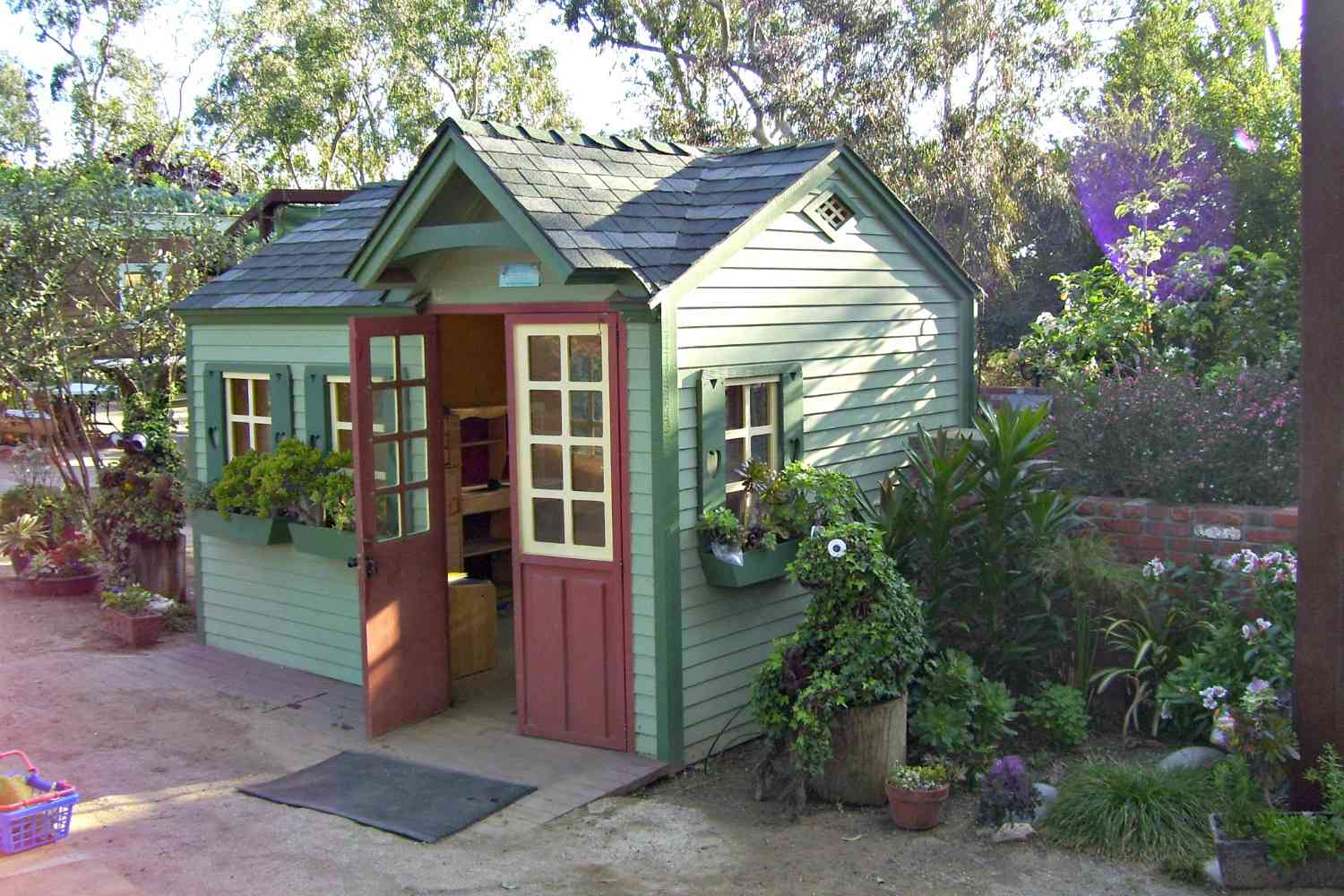

Add character and charm to the exterior of the shed through decorative elements and landscaping. Consider painting the exterior walls in a color that complements the surrounding environment or aligns with your personal style. Embrace creative techniques such as distressing or weathering to achieve a rustic and time-worn appearance, accentuating the shed's reclaimed pallet origins. Incorporate window boxes, trellises, or hanging planters to introduce greenery and floral accents, softening the shed's exterior and integrating it with the natural landscape.

Practical Additions

Enhance the functionality of the shed by integrating practical features such as a rainwater collection system, a small solar panel array for lighting, or a composting toilet for off-grid applications. These sustainable additions not only contribute to the shed's self-sufficiency but also align with eco-conscious principles. Explore options for climate control, such as insulation and ventilation, to ensure a comfortable interior environment year-round. Additionally, consider installing security measures, such as sturdy locks and motion-activated lighting, to safeguard the shed and its contents.

Personalization and Signage

Infuse the shed with your personal touch by incorporating signage, artwork, or custom detailing. Create a name plaque or a decorative sign for the shed, adding a distinctive identity to the structure. Embrace the opportunity to showcase your creativity through murals, mosaics, or handcrafted elements that reflect your individuality. These personalized touches not only make the shed uniquely yours but also contribute to its visual appeal and storytelling potential.

By meticulously attending to the finishing touches, you bring the pallet shed to its full potential, creating a space that is both functional and aesthetically pleasing. The thoughtful integration of interior customization, aesthetic enhancements, practical additions, and personalization culminates in a pallet shed that embodies your vision and serves as a versatile and inviting extension of your outdoor living space.

Conclusion

In conclusion, the journey of building a pallet shed is a testament to the transformative power of DIY construction and creative repurposing. From the initial planning and preparation to the meticulous execution of framing, roofing, and finishing touches, each phase of the project contributes to the realization of a functional, sustainable, and visually captivating outdoor structure.

The process of constructing a pallet shed goes beyond the mere assembly of reclaimed materials; it embodies a commitment to environmental consciousness, resourcefulness, and personalized craftsmanship. By repurposing pallets and integrating sustainable practices, builders can reduce their ecological footprint while creating a unique and purposeful addition to their property.

The versatility of a pallet shed extends beyond its utilitarian functions, offering a canvas for personal expression and customization. Through thoughtful interior design, aesthetic enhancements, and practical additions, the shed becomes a reflection of the builder's individuality and lifestyle, seamlessly blending into the natural landscape while serving as a hub for creativity and relaxation.

Furthermore, the journey of building a pallet shed fosters a sense of empowerment and skill development, as builders engage in hands-on construction, problem-solving, and the application of carpentry techniques. This DIY endeavor encourages a deeper connection to the built environment and instills a sense of pride in creating a tangible and enduring structure from reclaimed materials.

As the final nail is hammered, the last brushstroke applied, and the finishing touches come together, the pallet shed stands as a testament to the builder's vision, perseverance, and dedication to sustainable living. It embodies the potential for innovation, self-sufficiency, and the harmonious integration of human creativity with natural resources.

Ultimately, the completion of a pallet shed marks not just the end of a construction project, but the beginning of a new chapter in outdoor living. It offers a space for storage, hobbies, relaxation, and connection with nature, enriching the homeowner's lifestyle and contributing to a more sustainable and mindful approach to property enhancement.

In essence, the journey of building a pallet shed is a celebration of ingenuity, craftsmanship, and environmental stewardship, encapsulating the spirit of DIY construction and the timeless allure of repurposed materials. It stands as a testament to the transformative potential of sustainable building practices and the enduring charm of handcrafted structures in the modern world.