Home>Knowledge & Skills>Masonry & Tilework>How To Pour Concrete Steps

Masonry & Tilework

How To Pour Concrete Steps

Published: February 20, 2024

Our Editor-in-Chief brings a fresh perspective with his expertise in modern home technologies and eco-friendly solutions. Philip bridges tradition with innovation across a wide range of DIY topics.

Learn the step-by-step process of pouring concrete steps with our comprehensive guide. Perfect for DIY enthusiasts and professionals in masonry and tilework.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Twigandthistle.com, at no extra cost. Learn more)

Introduction

Pouring concrete steps is a fundamental skill in masonry and tilework, allowing you to create durable and aesthetically pleasing entryways for homes, businesses, and public spaces. Whether you're a seasoned professional or a DIY enthusiast, mastering the art of pouring concrete steps can significantly enhance the functionality and visual appeal of any property.

In this comprehensive guide, we will walk you through the step-by-step process of pouring concrete steps, providing valuable insights and expert tips to ensure a successful and rewarding project. From gathering the necessary materials and tools to the final finishing touches, you will gain a deep understanding of the techniques and considerations involved in this essential masonry endeavor.

By following the detailed instructions and best practices outlined in this guide, you will be equipped to tackle concrete step projects with confidence and precision. Whether you're aiming to enhance the curb appeal of your home or seeking to expand your skill set as a professional mason, the knowledge and techniques presented here will empower you to create sturdy, safe, and visually striking concrete steps that stand the test of time.

So, roll up your sleeves, gather your tools, and let's embark on this enriching journey into the art of pouring concrete steps. With a blend of practical guidance and creative flair, you'll soon discover the gratifying experience of transforming raw materials into functional and beautiful structures that leave a lasting impression. Let's dive in and uncover the secrets to mastering the craft of pouring concrete steps!

Read more: DIY Concrete Garage Baseboard Options

Step 1: Gather Materials and Tools

Before embarking on the process of pouring concrete steps, it's essential to gather all the necessary materials and tools to ensure a smooth and efficient workflow. By having everything at your disposal, you can minimize interruptions and focus on the task at hand, resulting in a more precise and satisfactory outcome.

Materials

- Concrete Mix: Select a high-quality concrete mix suitable for outdoor applications. Consider factors such as strength, durability, and weather resistance to ensure the longevity of the steps.

- Gravel and Sand: These materials are essential for creating a stable and well-draining base for the concrete steps. The right proportions of gravel and sand contribute to the overall strength and integrity of the structure.

- Rebar or Wire Mesh: Reinforcing the concrete with rebar or wire mesh enhances its tensile strength, reducing the risk of cracking and increasing the overall stability of the steps.

- Form Release Agent: This substance prevents the concrete from adhering to the formwork, facilitating easy removal and ensuring a smooth finish.

- Water: Clean water is crucial for achieving the proper consistency of the concrete mix. Ensure access to an adequate water source near the project site.

Tools

- Wheelbarrow: A sturdy wheelbarrow facilitates the transportation of materials and the mixing of concrete, providing mobility and convenience during the construction process.

- Shovel and Hoe: These tools are essential for mixing the concrete thoroughly and achieving the desired consistency before pouring.

- Level: A reliable level is indispensable for ensuring that the formwork and the concrete steps are perfectly aligned and level during construction.

- Trowels: Both finishing and pointing trowels are necessary for shaping and refining the surface of the concrete steps, allowing for precision and attention to detail.

- Hammer and Nails: These basic tools are required for assembling the formwork securely, ensuring that it can withstand the pressure of the concrete during pouring.

- Protective Gear: Safety glasses, gloves, and a dust mask are essential for personal protection during the handling and mixing of concrete materials.

By diligently gathering the specified materials and tools, you will establish a solid foundation for the subsequent steps in the concrete pouring process. This meticulous preparation sets the stage for a successful and rewarding construction experience, laying the groundwork for the creation of durable and visually appealing concrete steps.

Step 2: Prepare the Area

Proper preparation of the construction site is crucial for laying the groundwork for successful concrete step installation. This step sets the stage for a seamless and efficient pouring process, ensuring that the area is ready to accommodate the formwork and receive the concrete mixture. By meticulously preparing the area, you can mitigate potential challenges and create an optimal environment for constructing durable and visually appealing concrete steps.

Read more: How to Pour a DIY Basement Slab

Clear the Site

Begin by clearing the designated area where the concrete steps will be installed. Remove any debris, rocks, or vegetation that may impede the construction process. A clean and level surface is essential for establishing a solid foundation and ensuring the structural integrity of the steps.

Mark the Layout

Using stakes and string, mark the layout of the concrete steps according to the desired dimensions and design. Carefully outline the boundaries of the steps, taking into account the rise and run measurements to achieve the desired slope and tread dimensions. Accurate marking is essential for guiding the placement of the formwork and ensuring that the steps conform to the intended design.

Excavate and Level

Excavate the marked area to the required depth, accounting for the thickness of the concrete steps and the base materials. Use a shovel and a level to ensure that the excavated area is uniform and level, providing a stable foundation for the steps. Proper excavation and leveling are critical for preventing uneven settling and maintaining the structural integrity of the finished steps.

Install Base Materials

Once the excavation is complete, add a layer of compacted gravel to the bottom of the prepared area. The gravel serves as a base material, promoting drainage and providing a stable sub-base for the concrete steps. Compact the gravel thoroughly to create a solid and even foundation that can support the weight of the concrete and withstand external pressures.

Read more: How To Make A Concrete Porch

Verify Alignment and Grade

After installing the base materials, verify the alignment and grade of the excavated area using a level and straightedge. Ensure that the surface is uniformly graded and sloped according to the intended design, allowing for proper water runoff and overall stability. Attention to detail at this stage is essential for laying the groundwork for precise and structurally sound concrete steps.

By meticulously preparing the area for concrete step installation, you establish a solid foundation for the subsequent stages of the construction process. This meticulous approach sets the stage for a seamless and efficient pouring process, ensuring that the area is ready to accommodate the formwork and receive the concrete mixture. With careful attention to detail and adherence to best practices, you can create a conducive environment for constructing durable and visually appealing concrete steps.

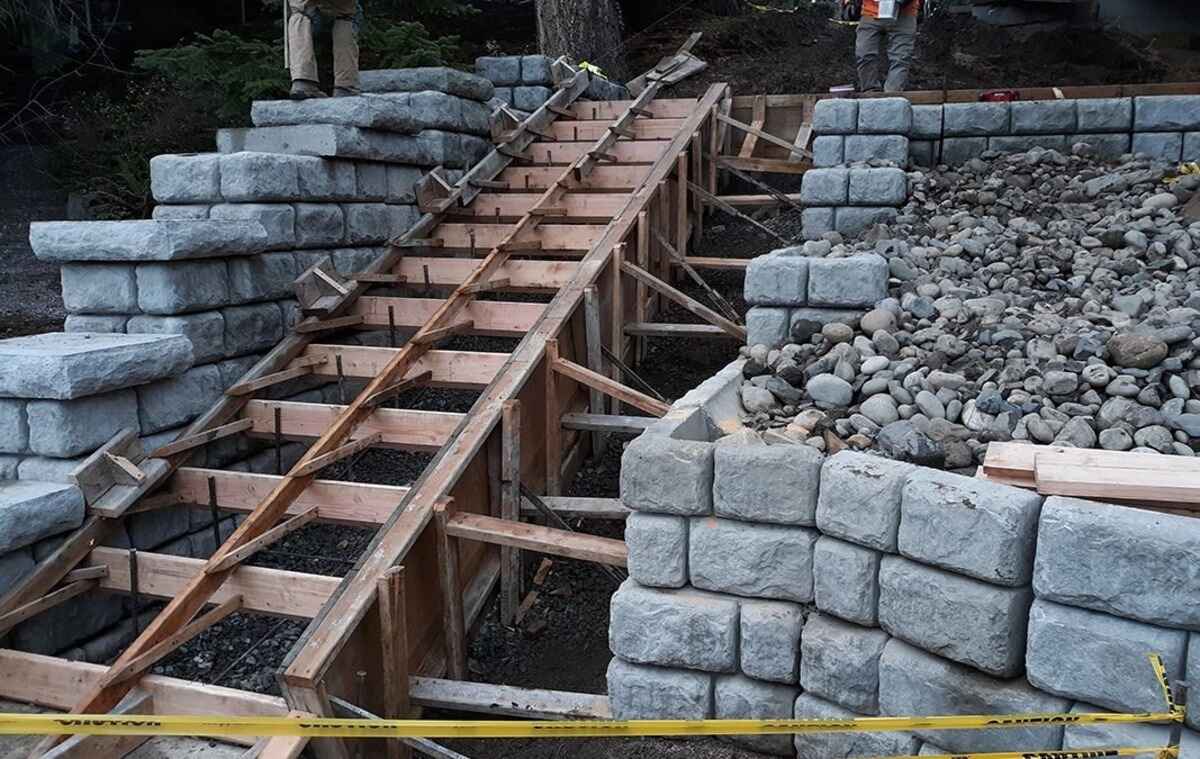

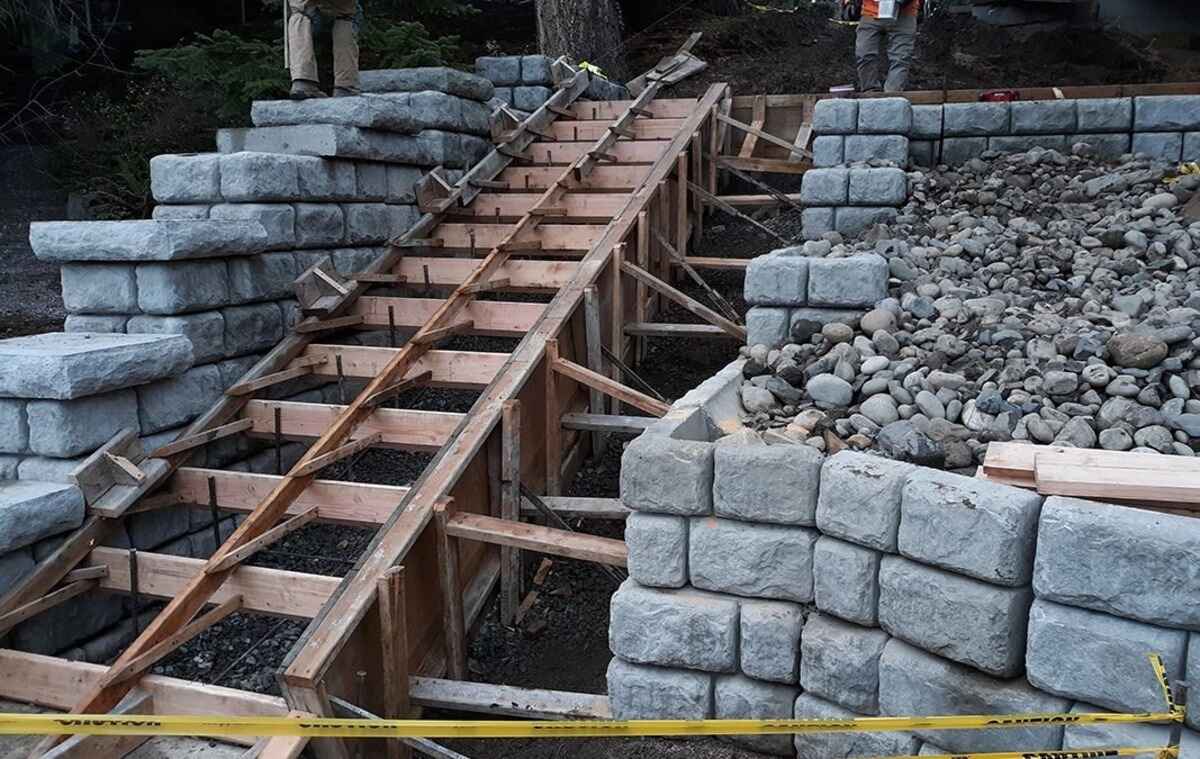

Step 3: Build the Formwork

Building the formwork is a critical step in the process of pouring concrete steps, as it establishes the framework that will contain the concrete mixture and define the shape and dimensions of the steps. Properly constructed formwork ensures that the concrete is poured with precision, resulting in structurally sound and visually appealing steps that meet the intended design specifications. Here's a detailed breakdown of the essential steps involved in building the formwork for concrete steps:

Design Considerations

Before constructing the formwork, carefully review the design specifications and dimensions for the concrete steps. Consider the desired rise and run measurements, as well as the overall layout and configuration of the steps. Take into account any decorative features or specialized designs that may require custom formwork elements. By understanding the design requirements, you can plan the formwork construction process with precision and attention to detail.

Select Formwork Materials

Choose high-quality formwork materials that can withstand the pressure of the concrete and maintain their shape during the pouring and curing process. Common formwork materials include plywood, dimensional lumber, and engineered formwork systems. Ensure that the materials are straight, free from defects, and capable of producing smooth and uniform surfaces on the finished concrete steps.

Read more: How to Build a Concrete Vanity Top

Assembly and Installation

Begin by cutting the formwork materials to the appropriate dimensions based on the design specifications. Assemble the individual formwork components, ensuring tight and secure joints to prevent concrete leakage. Use sturdy fasteners, such as screws or nails, to secure the formwork in place, maintaining the desired shape and alignment. Pay close attention to the vertical and horizontal alignment of the formwork, as any deviations can impact the final appearance and functionality of the steps.

Reinforcement and Bracing

For larger or more complex concrete steps, consider reinforcing the formwork with additional bracing and supports to withstand the pressure of the concrete. Diagonal bracing and cross supports can enhance the stability of the formwork, preventing bulging or shifting during the pouring process. Verify the integrity of the formwork structure before proceeding to the next stage, ensuring that it can accommodate the weight and volume of the concrete without deformation.

Form Release Agent

Apply a form release agent to the interior surfaces of the formwork to prevent the concrete from adhering to the wood or other materials. This facilitates easy removal of the formwork after the concrete has cured, resulting in clean and well-defined step surfaces. Ensure thorough coverage of the formwork with the release agent, following the manufacturer's recommendations for application and drying times.

By meticulously following these steps and best practices, you can build formwork that provides a solid and precise framework for pouring concrete steps. The attention to detail and craftsmanship invested in constructing the formwork sets the stage for the successful realization of the design vision, resulting in durable, well-defined, and visually striking concrete steps.

Step 4: Mix and Pour the Concrete

Mixing and pouring the concrete is a pivotal phase in the construction of concrete steps, demanding precision, attention to detail, and a thorough understanding of the concrete mixing process. This step involves blending the concrete mix to the appropriate consistency and pouring it into the prepared formwork, laying the foundation for sturdy and visually appealing steps. Here's a detailed breakdown of the essential procedures involved in mixing and pouring the concrete for your concrete steps:

Read more: How To Build A Concrete Block Shed

Concrete Mix Preparation

Begin by carefully following the manufacturer's instructions for mixing the concrete. Measure the precise quantities of concrete mix, gravel, and sand according to the recommended ratios, ensuring the proper balance of materials for optimal strength and workability. Use a wheelbarrow or mixing container to combine the dry ingredients thoroughly, creating a uniform blend that forms the basis of the concrete mixture.

Water Addition and Mixing

Gradually add clean water to the dry concrete mix, using a shovel or hoe to incorporate the water evenly. Aim for a consistent and workable consistency, ensuring that the concrete is neither too dry nor too soupy. Thoroughly mix the concrete and water, paying close attention to the uniform distribution of moisture throughout the mixture. Achieving the correct consistency is crucial for facilitating proper compaction and ensuring the structural integrity of the concrete steps.

Pouring and Compaction

Carefully transfer the mixed concrete into the prepared formwork, starting from the lowest step and progressing upwards. Use a shovel or trowel to distribute the concrete evenly within the formwork, filling all the corners and edges to create a uniform surface. As the concrete is poured, employ a vibrating tool or rod to compact the mixture and eliminate air pockets, promoting the consolidation of the concrete and enhancing its strength and durability.

Finishing Touches

After pouring the concrete, use a screed or straightedge to level the surface of each step, ensuring a smooth and uniform finish. Pay attention to the alignment and elevation of the steps, making any necessary adjustments to achieve the desired dimensions and slope. Employ a trowel to refine the surface, smoothing out imperfections and creating a visually appealing texture that enhances the overall aesthetic of the concrete steps.

By meticulously following these procedures and best practices, you can effectively mix and pour the concrete for your concrete steps, laying the groundwork for the successful realization of your construction project. The precision and care invested in this phase contribute to the creation of durable, well-defined, and visually striking concrete steps that elevate the functionality and aesthetic appeal of any space.

Read more: How to Resurface Concrete Floor in Garage

Step 5: Finish and Cure the Concrete Steps

Once the concrete has been poured into the formwork, the process of finishing and curing the concrete steps is essential to ensure their structural integrity, visual appeal, and long-term durability. This phase involves meticulous attention to detail and adherence to best practices, allowing the concrete to achieve its full strength and aesthetic potential. Here's a comprehensive overview of the crucial steps involved in finishing and curing the concrete steps:

Surface Finishing

After the concrete has been poured and leveled, the surface of each step requires careful attention to achieve a smooth and visually appealing finish. Utilizing a trowel, the concrete surface is meticulously worked to eliminate imperfections, fill voids, and create a uniform texture. This process, known as "floating," enhances the overall appearance of the steps and contributes to their aesthetic appeal.

Edging and Detailing

To refine the edges and contours of the concrete steps, specialized tools such as edging trowels are employed to create clean and defined edges. This step adds a professional touch to the finished product, ensuring that the steps exhibit a polished and well-defined appearance. Attention to detail during this phase contributes to the overall visual impact of the concrete steps.

Curing Process

Proper curing is crucial for allowing the concrete to achieve its maximum strength and durability. After the initial finishing, the concrete steps are covered with a curing compound or moist curing method to retain moisture and facilitate the hydration process. This essential step prevents premature drying and cracking, allowing the concrete to develop its full potential strength over time.

Read more: DIY Outdoor Concrete Countertops

Protection and Maintenance

Following the initial curing process, it's important to protect the newly poured concrete steps from excessive foot traffic and environmental stress. Implementing temporary barriers or cautionary signage can help prevent damage during the critical early stages of curing. Additionally, regular maintenance, such as cleaning and sealing, can prolong the lifespan and visual appeal of the concrete steps.

By meticulously following these steps and best practices, you can ensure that the finished concrete steps exhibit a high level of craftsmanship, structural integrity, and aesthetic appeal. The combination of precise finishing techniques and diligent curing processes contributes to the creation of durable, visually striking, and long-lasting concrete steps that enhance the functionality and beauty of any architectural space.

Conclusion

In conclusion, the process of pouring concrete steps encompasses a blend of technical expertise, meticulous craftsmanship, and creative vision. From the initial preparation of the construction site to the final finishing and curing stages, each step plays a pivotal role in shaping the outcome of the project. By adhering to best practices and leveraging a deep understanding of masonry and tilework, individuals can embark on this enriching journey with confidence and precision.

The art of pouring concrete steps extends beyond the mere act of construction; it embodies the fusion of functionality and aesthetics. The resulting steps serve as more than just a means of vertical circulation; they become integral elements of architectural design, enhancing the visual appeal and usability of the surrounding space. Whether adorning the entrance of a residence or defining the pathways of a commercial property, well-crafted concrete steps leave a lasting impression, reflecting the skill and dedication invested in their creation.

Furthermore, the process of pouring concrete steps offers a canvas for personal expression and innovation. Through thoughtful design considerations, such as the selection of formwork materials and the application of finishing techniques, individuals can infuse their unique style and craftsmanship into the project. This creative aspect elevates the construction process from a mere task to an opportunity for self-expression and artistic contribution.

Moreover, the durability and longevity of properly poured concrete steps underscore the significance of meticulous attention to detail and adherence to industry best practices. By following the prescribed steps and techniques, individuals can ensure that the resulting steps withstand the test of time, weathering the elements and maintaining their structural integrity for years to come.

In essence, the process of pouring concrete steps represents a harmonious blend of technical proficiency, creative expression, and enduring craftsmanship. By embracing this multifaceted approach, individuals can transform raw materials into functional and visually captivating structures, leaving a lasting legacy of skill and artistry. As the concrete cures and the finishing touches are applied, the culmination of this process stands as a testament to the transformative power of masonry and tilework, enriching the built environment and inspiring admiration for generations to come.