Home>Home & Furniture>Roof>How To Build A Shed Roof

Roof

How To Build A Shed Roof

Published: February 20, 2024

Editor-in-Chief with a decade in home renovation and a passion for vintage furniture. Diane is known for her weekend treasure hunts at flea markets, enriching our content with unique style insights.

Learn how to build a shed roof with our comprehensive guide. Find tips and techniques for constructing a sturdy and durable roof for your shed.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Twigandthistle.com, at no extra cost. Learn more)

Introduction

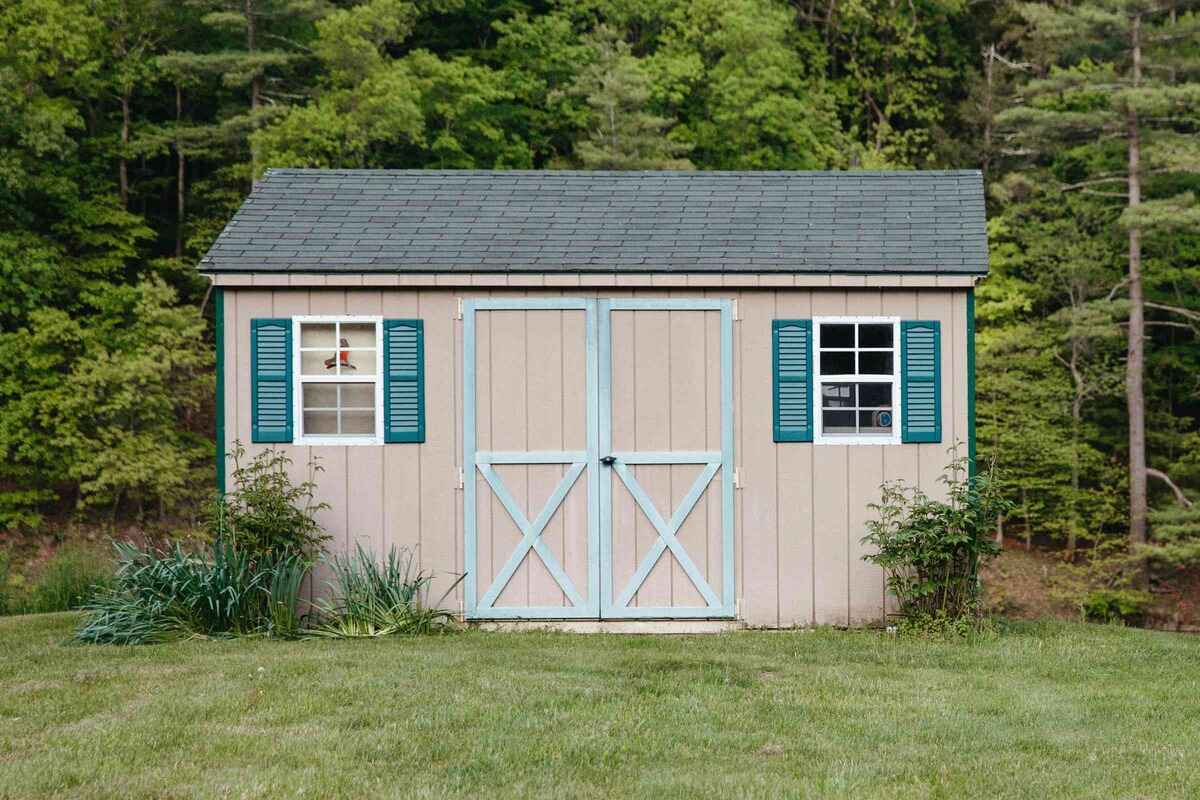

Building a shed roof is a fundamental aspect of constructing a sturdy and reliable outdoor structure. Whether you're planning to create a storage shed, garden shed, or a cozy backyard retreat, the roof plays a crucial role in providing protection against the elements. A well-built shed roof not only enhances the aesthetic appeal of the structure but also ensures durability and longevity.

In this comprehensive guide, we will walk you through the step-by-step process of constructing a shed roof. From gathering the necessary materials and tools to the final touches of sealing the roof, each stage is essential in creating a functional and visually appealing roofing system for your shed.

By following these instructions, you will gain the knowledge and confidence to tackle this project with precision and skill. Whether you're a seasoned DIY enthusiast or a beginner looking to expand your construction skills, this guide will equip you with the essential know-how to build a shed roof that meets your specific needs and complements the overall design of your outdoor space.

So, roll up your sleeves, gather your tools, and let's embark on this rewarding journey of building a shed roof that will stand the test of time. With careful planning, attention to detail, and a touch of creativity, you'll soon be enjoying the satisfaction of completing a practical and visually appealing roofing structure for your shed.

Read more: How To Build A Single Slope Shed Roof

Step 1: Gather Materials and Tools

Before diving into the construction of a shed roof, it's crucial to gather all the necessary materials and tools. This step sets the foundation for a smooth and efficient building process. Here's a detailed breakdown of the essential items you'll need:

Materials:

- Lumber: Select high-quality lumber for the roof framing, including rafters and ridge boards. The dimensions of the lumber will depend on the size and design of your shed.

- Roof Sheathing: Choose durable plywood or oriented strand board (OSB) for the roof sheathing. This material provides a solid base for the roofing material and adds structural integrity to the roof.

- Roofing Material: Depending on your preference and local climate, opt for asphalt shingles, metal roofing panels, or other suitable roofing materials. Ensure that the chosen material offers excellent weather resistance and longevity.

- Fasteners: Stock up on nails, screws, and other fasteners required for securing the roof components and sheathing.

- Roofing Underlayment: Consider adding a waterproof roofing underlayment to provide an extra layer of protection against moisture infiltration.

- Sealant: Acquire high-quality roofing sealant to ensure proper waterproofing and weatherproofing of the roof.

Tools:

- Circular Saw: A reliable circular saw will be indispensable for cutting lumber and sheathing to the required dimensions.

- Level: Ensure you have a sturdy level to maintain the accuracy and alignment of the roof components during installation.

- Hammer and Nail Gun: Both a hammer and a nail gun will come in handy for securing the framing and sheathing in place.

- Measuring Tape: Precision is key in roof construction, so a quality measuring tape is essential for accurate cuts and placements.

- Roofing Square: This tool is essential for marking and cutting accurate angles on the rafters and other roof components.

- Ladder: Safety is paramount, and a sturdy ladder will enable safe access to the roof during the construction process.

By ensuring that you have all the required materials and tools at your disposal, you'll be well-prepared to proceed with confidence to the next stage of building your shed roof. This careful preparation sets the stage for a successful and rewarding construction experience.

Step 2: Measure and Cut Roof Rafters

The process of measuring and cutting roof rafters is a critical phase in building a shed roof. Roof rafters form the framework that supports the roof's structure, providing essential strength and stability. To ensure the precise construction of the roof, meticulous attention to detail and accurate measurements are paramount.

Read more: How To Build A Slanted Shed Roof

Measuring the Roof Rafters

Before cutting any lumber, it's crucial to calculate the dimensions and angles of the roof rafters. The pitch and span of the roof will determine the length and angles of the rafters. The pitch refers to the slope of the roof, while the span represents the distance between the walls where the rafters will be installed.

Using a roofing square and a measuring tape, mark and measure the length of each rafter, taking into account any overhang that may be required. Additionally, calculate the angles at which the rafters will be cut to ensure a snug fit and proper alignment when installed.

Cutting the Roof Rafters

Once the measurements and angles have been accurately determined, it's time to proceed with cutting the roof rafters. A circular saw is the ideal tool for this task, allowing for precise and clean cuts. Carefully follow the marked guidelines to ensure that each rafter is cut to the exact specifications required for your shed roof.

It's important to double-check the accuracy of each cut before moving on to the installation phase. Consistency in the dimensions and angles of the rafters is crucial to the overall stability and integrity of the roof structure.

By meticulously measuring and cutting the roof rafters with precision, you are laying the foundation for a well-constructed and reliable shed roof. This meticulous attention to detail ensures that the roof rafters will seamlessly integrate into the overall structure, setting the stage for the next phase of the roof construction process.

With the roof rafters accurately measured and cut, you are now ready to progress to the next stage of installing these essential components as part of the shed roof assembly.

Step 3: Install Roof Rafters

With the roof rafters accurately measured and cut to precision, the next crucial step in building a shed roof is the installation of these essential components. Roof rafters form the framework that supports the entire roofing structure, providing the necessary strength and stability to withstand various weather conditions.

Preparing for Installation

Before commencing the installation process, it's imperative to ensure that the top plates of the shed walls are level and securely anchored. This foundational preparation sets the stage for the seamless installation of the roof rafters. Additionally, having a reliable assistant to help with lifting and positioning the rafters can significantly streamline the installation process and enhance safety.

Read more: How To Build A Shed

Positioning and Securing the Rafters

Carefully lift each rafter into position, ensuring that they align precisely with the layout and markings on the top plates. Utilizing a level is crucial at this stage to confirm that the rafters are plumb and properly aligned. Secure the rafters in place using appropriate fasteners, such as nails or screws, ensuring a strong and stable connection between the rafters and the top plates.

Bracing and Alignment

As the installation progresses, temporary bracing can be utilized to maintain the alignment and stability of the rafters. This step is particularly important when working on larger roof structures, as it helps prevent any shifting or misalignment during the installation process. Ensuring that the rafters are uniformly spaced and aligned according to the predetermined layout is essential for the overall integrity of the roof framework.

Completing the Rafter Installation

Once all the roof rafters are securely installed and aligned, a final inspection should be conducted to verify the stability and alignment of the entire rafter framework. Any necessary adjustments or additional bracing should be implemented at this stage to guarantee the structural integrity of the roof framework.

By meticulously following the steps outlined for installing the roof rafters, you are laying the groundwork for a robust and reliable shed roof. The precise positioning and secure attachment of the rafters are essential for the overall stability and durability of the roof structure, setting the stage for the subsequent phases of constructing a functional and visually appealing shed roof.

Step 4: Add Roof Sheathing

Once the roof rafters are securely in place, the next crucial step in building a shed roof is the addition of roof sheathing. Roof sheathing serves as the foundation for the roofing material and provides essential structural support to the roof. This phase of the construction process plays a pivotal role in ensuring the overall integrity and durability of the shed roof.

Read more: How To Build Shed Foundation

Selecting and Preparing the Sheathing Material

Before adding the roof sheathing, it's essential to select the appropriate material that aligns with the specific requirements of your shed roof. Oriented strand board (OSB) and plywood are commonly used for roof sheathing due to their strength and durability. The selected sheathing material should be of high quality and suitable thickness to provide adequate support for the roofing material.

Prior to installation, the sheathing material should be cut to fit the dimensions of the roof surface, ensuring a precise and snug fit. Careful attention should be given to aligning the sheathing panels to minimize waste and optimize the structural integrity of the roof.

Securing the Sheathing in Place

Once the sheathing material is prepared, it's time to secure it to the roof rafters. Starting from the bottom edge of the roof, the sheathing panels are positioned and fastened to the rafters using appropriate fasteners, such as nails or screws. It's crucial to follow the specified nailing pattern recommended for the chosen sheathing material to ensure uniform support and stability across the entire roof surface.

As the sheathing installation progresses, it's important to stagger the sheathing panels to enhance the overall strength and prevent weak points in the roof structure. Additionally, ensuring that the sheathing panels are properly aligned and securely fastened is essential for creating a solid foundation for the roofing material.

Ensuring Structural Integrity

Throughout the installation process, periodic checks should be conducted to verify the alignment, stability, and uniformity of the sheathing panels. Any necessary adjustments or additional fastening should be implemented to address any irregularities and ensure the structural integrity of the roof sheathing.

By meticulously adding the roof sheathing with precision and attention to detail, you are establishing a solid and reliable foundation for the final phase of installing the roofing material. The careful execution of this step is instrumental in creating a robust and durable shed roof that will provide long-lasting protection and functionality.

With the roof sheathing securely in place, you are now ready to progress to the next stage of installing the chosen roofing material, bringing you one step closer to completing your well-constructed shed roof.

Step 5: Install Roofing Material

With the roof sheathing securely in place, the next pivotal step in the construction of a shed roof is the installation of the roofing material. The choice of roofing material significantly impacts the shed's aesthetic appeal, weather resistance, and overall durability. Whether opting for traditional asphalt shingles, sleek metal roofing panels, or alternative roofing options, the installation process demands precision and attention to detail to ensure a watertight and visually appealing roof.

Preparing for Installation

Before commencing the installation of the roofing material, it's essential to inspect the underlying roof sheathing to confirm its structural integrity and uniformity. Any necessary repairs or adjustments to the sheathing should be addressed before proceeding with the installation. Additionally, ensuring that the roof surface is clean, free of debris, and properly aligned sets the stage for a seamless installation process.

Selecting the Appropriate Method

The method of installing the chosen roofing material will vary based on the specific type of material selected. For asphalt shingles, the installation typically involves overlapping individual shingles in a staggered pattern, secured with appropriate roofing nails. Metal roofing panels, on the other hand, may require specialized fastening techniques to ensure a secure and weather-resistant fit. It's crucial to follow the manufacturer's guidelines and recommended installation practices for the chosen roofing material to achieve optimal results.

Precision and Alignment

Maintaining precision and alignment during the installation process is paramount to ensure a watertight and visually appealing shed roof. Each roofing material has unique installation requirements, including proper overlap, alignment, and fastening methods. Careful attention should be given to the placement of each roofing component to minimize the risk of water infiltration and enhance the overall aesthetic quality of the roof.

Weatherproofing and Sealing

Once the roofing material is securely installed, attention should be directed towards weatherproofing and sealing the roof to enhance its longevity and resistance to the elements. This may involve applying a waterproof sealant along the seams and edges of the roofing material to create a barrier against moisture infiltration. Additionally, ensuring that all flashing and penetrations are properly sealed further fortifies the shed roof against potential water damage.

Final Inspection

Upon completing the installation and sealing of the roofing material, a comprehensive inspection should be conducted to verify the integrity and weather resistance of the shed roof. Any areas requiring additional sealing or adjustments should be promptly addressed to ensure that the roof provides reliable protection and durability.

By meticulously following the installation guidelines specific to the chosen roofing material, you are one step closer to completing a well-constructed and visually appealing shed roof. The installation of the roofing material represents a pivotal phase in the construction process, bringing you closer to enjoying a functional and aesthetically pleasing outdoor structure.

Step 6: Finish and Seal the Roof

With the roofing material securely installed, the final phase of building a shed roof involves the critical tasks of finishing and sealing the roof. This stage is essential for ensuring the long-term durability, weather resistance, and overall aesthetic appeal of the completed roof structure.

Trimming and Overhangs

To achieve a polished and professional appearance, attention should be given to trimming any excess roofing material and creating uniform overhangs along the edges of the roof. Careful trimming and shaping of the roofing material contribute to the overall visual appeal of the shed roof while providing essential protection against water runoff and weather elements.

Ridge Cap Installation

The installation of a ridge cap, specifically designed for the chosen roofing material, serves as the finishing touch that enhances the weather resistance and visual coherence of the roof. The ridge cap is meticulously positioned along the peak of the roof, providing a protective barrier against water infiltration and reinforcing the overall integrity of the roofing structure.

Read more: How To Build An Office Shed

Sealing and Weatherproofing

Applying a high-quality roofing sealant to critical areas, including the ridge cap, flashing, and any exposed nail heads, is crucial for fortifying the shed roof against potential water penetration. This meticulous sealing process serves to safeguard the roof against moisture intrusion, thereby extending its lifespan and enhancing its resilience in the face of varying weather conditions.

Aesthetic Touches

In addition to the functional aspects of finishing and sealing the roof, attention can be directed towards aesthetic touches that elevate the visual appeal of the shed roof. This may include the application of protective coatings or treatments that enhance the color vibrancy and UV resistance of the roofing material, contributing to a more vibrant and enduring aesthetic.

Final Inspection and Maintenance Guidelines

Upon completing the finishing and sealing of the roof, a comprehensive inspection should be conducted to ensure that all elements are securely in place and effectively weatherproofed. Additionally, providing maintenance guidelines to preserve the integrity and longevity of the shed roof, such as periodic inspections and recommended upkeep practices, further contributes to the overall success of the roofing project.

By meticulously attending to the finishing and sealing of the shed roof, you are not only enhancing its durability and weather resistance but also elevating its visual appeal and longevity. This final phase marks the culmination of a well-executed and comprehensive construction process, resulting in a functional, resilient, and aesthetically pleasing shed roof that will stand the test of time.

Conclusion

In conclusion, the process of building a shed roof encompasses a series of meticulous steps that culminate in the creation of a durable, weather-resistant, and visually appealing roofing structure. From the initial gathering of materials and tools to the final touches of sealing and finishing, each stage plays a crucial role in ensuring the overall integrity and functionality of the shed roof.

Throughout this comprehensive guide, we have delved into the intricacies of constructing a shed roof, emphasizing the importance of precision, attention to detail, and adherence to best practices. By meticulously measuring and cutting the roof rafters, installing the roof sheathing, and carefully positioning and securing the roofing material, the foundation is laid for a robust and reliable roof that provides essential protection for the contents of the shed.

The significance of weatherproofing and sealing the roof cannot be overstated, as these final steps serve to fortify the shed roof against the elements, extending its lifespan and enhancing its resilience. Additionally, the aesthetic touches applied during the finishing phase contribute to the overall visual appeal of the roof, elevating its presence within the outdoor space.

As a result of following the step-by-step process outlined in this guide, you have gained the knowledge and confidence to embark on the rewarding journey of building a shed roof that meets your specific needs and complements the design of your outdoor space. Whether you are a seasoned DIY enthusiast or a beginner looking to expand your construction skills, the insights provided here equip you with the essential know-how to create a functional and visually appealing roofing structure.

Ultimately, the completion of a well-constructed shed roof not only enhances the practicality of your outdoor space but also adds a touch of craftsmanship and personalization to your property. The satisfaction of completing such a project resonates in the knowledge that you have contributed to the enhancement and functionality of your living environment.

In essence, the construction of a shed roof is a testament to the fusion of practicality and creativity, resulting in a structure that not only serves a utilitarian purpose but also adds aesthetic value to your outdoor space. With the completion of your shed roof, you are poised to enjoy the benefits of a well-protected and visually appealing addition to your property for years to come.