Home>Home & Furniture>Roof>DIY Shed Roof Framing With Overhang: Step-by-Step Guide

Roof

DIY Shed Roof Framing With Overhang: Step-by-Step Guide

Published: February 21, 2024

Editor-in-Chief with a decade in home renovation and a passion for vintage furniture. Diane is known for her weekend treasure hunts at flea markets, enriching our content with unique style insights.

Learn how to frame a shed roof with overhang in this step-by-step guide. Discover essential DIY tips for building a sturdy roof.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Twigandthistle.com, at no extra cost. Learn more)

Introduction

When it comes to building a shed, the roof framing is a critical aspect that requires careful planning and execution. A well-constructed roof not only enhances the aesthetic appeal of the shed but also provides essential protection against the elements. One popular design feature that adds both functionality and visual interest to a shed roof is the overhang. An overhang not only provides additional shelter from rain and sun but also adds a touch of architectural elegance to the structure.

In this comprehensive guide, we will walk you through the step-by-step process of framing a shed roof with an overhang. Whether you're a seasoned DIY enthusiast or a novice builder, this guide will equip you with the knowledge and skills needed to tackle this project with confidence. From measuring and marking the shed to installing the roof trusses and adding the finishing touches, we've got you covered.

By following this guide, you'll gain a deeper understanding of the intricacies involved in roof framing, including the selection of materials, the use of essential tools, and the precise assembly of roof trusses. Additionally, we'll explore the importance of proper roof sheathing and the installation of roofing materials to ensure a durable and weather-resistant roof.

Furthermore, we'll delve into the process of adding an overhang to the roof, discussing the functional benefits of this feature and the techniques for achieving a professional-looking result. Whether you're aiming to create a cozy outdoor space or simply enhance the overall design of your shed, the addition of an overhang can make a significant difference.

By the end of this guide, you'll be well-equipped to embark on your DIY shed roof framing project, armed with the knowledge and confidence to bring your vision to life. So, roll up your sleeves, gather your tools, and let's dive into the rewarding journey of building a shed roof with a stylish overhang.

Materials and Tools Needed

Before embarking on the DIY shed roof framing project, it's essential to gather the necessary materials and tools to ensure a smooth and efficient construction process. Here's a comprehensive list of the items you'll need to have on hand:

Materials:

- Lumber: Select high-quality lumber for the construction of the roof trusses, rafters, and overhang framing. The specific dimensions and quantity will depend on the size and design of your shed.

- Roof Sheathing: Choose durable plywood or oriented strand board (OSB) for the roof sheathing to provide a solid base for the roofing material.

- Roofing Material: Opt for asphalt shingles, metal roofing panels, or another suitable roofing material to protect the shed from the elements.

- Fasteners: Stock up on nails, screws, and other fasteners required for securing the various components of the roof framing and sheathing.

- Drip Edge and Flashing: Invest in drip edge and flashing to prevent water infiltration and ensure proper drainage on the roof.

- Overhang Material: If you plan to extend the roof with an overhang, you'll need additional lumber for framing and soffit material for the underside of the overhang.

Tools:

- Measuring Tape: A reliable measuring tape is essential for accurately determining the dimensions of the shed and the required lengths of lumber.

- Circular Saw: A circular saw will be indispensable for cutting lumber to the precise lengths needed for the roof trusses and rafters.

- Power Drill: Invest in a power drill with a set of drill bits for driving screws and creating pilot holes for nails.

- Hammer: A sturdy hammer is a fundamental tool for securing fasteners and making minor adjustments during the construction process.

- Level: Ensure that the roof framing is perfectly aligned by using a level to check for straightness and evenness.

- Ladder: Depending on the height of your shed, a stable ladder will be necessary for accessing the roof and installing the trusses.

By gathering these materials and tools in advance, you'll be well-prepared to tackle each phase of the shed roof framing project with confidence and efficiency. With everything at your disposal, you can proceed to the next step of measuring and marking the shed for the construction of the roof trusses.

Step 1: Measure and Mark the Shed

Before diving into the construction of the roof trusses, it's crucial to begin with precise measurements and markings on the shed. This initial step sets the foundation for the entire roof framing process, ensuring that the subsequent components fit together seamlessly.

Start by gathering your measuring tape, pencil, and a sturdy ladder. Begin at the base of the shed, measuring the length and width to determine the exact dimensions of the roof. It's essential to account for any existing overhang or desired extension when measuring the width of the roof. Additionally, consider the pitch or slope of the roof, as this will influence the design and construction of the roof trusses.

Once the measurements are recorded, mark the locations for the roof trusses along the top plate of the shed walls. Spacing the trusses evenly is crucial for distributing the weight of the roof and ensuring structural integrity. Typically, trusses are spaced 24 inches apart, but this may vary based on the specific requirements of your shed design.

After marking the truss locations, it's time to establish the position of the overhang, if applicable. Determine the desired overhang length and mark it along the edges of the shed. This step is essential for visualizing the extended roof structure and planning the framing for the overhang.

As you proceed with the marking process, double-check the accuracy of your measurements and markings to avoid discrepancies during the construction phase. Precision at this stage will streamline the subsequent tasks and contribute to the overall stability and aesthetics of the shed roof.

By meticulously measuring and marking the shed, you lay the groundwork for a successful roof framing project. This preparatory phase sets the stage for the precise construction of roof trusses and ensures that the final result aligns with your vision for the shed. With the shed accurately measured and marked, you're ready to move on to the next phase of cutting and assembling the roof trusses.

Read more: How to Build a DIY Door Overhang

Step 2: Cut and Assemble the Roof Trusses

With the shed accurately measured and marked, the next crucial step in framing the shed roof is to cut and assemble the roof trusses. Roof trusses are the structural framework that supports the roof and distributes its weight evenly, making them a fundamental element of the shed's construction.

Cutting the Truss Components

Begin by gathering the lumber specified for the truss construction, ensuring that it is of high quality and suitable for load-bearing purposes. Using the precise measurements and angles determined during the marking phase, carefully cut the individual components of the trusses, including the top and bottom chords, web members, and gussets.

The top and bottom chords form the horizontal top and bottom edges of the truss, while the web members connect them diagonally to provide structural support. It's crucial to cut these components with precision, as any discrepancies in length or angle can compromise the integrity of the truss assembly.

Assembling the Trusses

Once the truss components are cut to the required dimensions, it's time to assemble them into complete truss units. Lay out the top and bottom chords parallel to each other, then position the web members at the specified angles and intervals between the chords. Secure the connections using appropriate fasteners, ensuring that the truss components are aligned and the angles are accurate.

To reinforce the connections and enhance the strength of the trusses, gussets are added at the junctions of the chords and web members. These gussets, typically made of plywood, are secured in place using nails or screws, effectively binding the truss components together and creating a robust framework.

Quality Assurance

Throughout the cutting and assembly process, it's essential to maintain a keen eye for detail and accuracy. Verify that each truss is constructed according to the predetermined specifications, with precise angles, lengths, and secure connections. Consistency in truss construction is paramount to ensure uniform support for the roof and prevent any structural issues down the line.

By meticulously cutting and assembling the roof trusses, you establish the foundational framework that will uphold the shed's roof with strength and stability. With the trusses ready for installation, the next phase of the project involves positioning and securing them on the shed, bringing the roof structure one step closer to completion.

Read more: How To Build An A Frame Roof

Step 3: Install the Trusses on the Shed

With the roof trusses meticulously constructed, the focus now shifts to the pivotal task of installing them on the shed. This phase marks a significant stride in the shed roof framing process, as the trusses form the structural framework that will support the roof and ensure its stability and durability.

Preparing for Installation

Before hoisting the trusses into position, it's essential to enlist the assistance of at least one additional person to ensure a safe and efficient installation process. Additionally, inspect the shed's walls and top plates to confirm that they are structurally sound and capable of bearing the weight of the trusses. Any necessary repairs or reinforcements should be addressed before proceeding with the installation.

Positioning the Trusses

Using a stable ladder or scaffolding, carefully lift each truss into place, aligning it with the marked locations on the shed's walls. It's crucial to maintain the specified spacing between trusses, typically 24 inches on center, to evenly distribute the load of the roof. As each truss is positioned, temporarily brace it in place to prevent shifting or tilting during the installation process.

Securing the Trusses

Once all the trusses are in position, secure them to the shed's walls by fastening them to the top plates using appropriate fasteners, such as nails or screws. It's imperative to ensure that the trusses are plumb and properly aligned before permanently affixing them to the structure. Utilizing a level during this phase can help verify the vertical alignment of the trusses, guaranteeing a stable and uniform roof structure.

Read more: How To Build A Pitched Roof Frame

Reinforcing the Connections

To enhance the stability and load-bearing capacity of the trusses, additional bracing may be installed diagonally between the trusses. These braces serve to minimize lateral movement and provide crucial support, particularly in regions prone to high winds or heavy snow loads. By reinforcing the connections between trusses, the overall resilience of the roof structure is significantly bolstered.

Progressing Toward Completion

As the trusses are securely installed and reinforced, the shed's roof begins to take shape, laying the groundwork for the subsequent phases of the roof framing process. With the trusses in place, the next steps involve adding the essential roof sheathing, followed by the installation of the chosen roofing material to provide weatherproofing and aesthetic appeal.

By methodically installing the trusses on the shed, you establish the fundamental framework for a robust and reliable roof structure. This critical phase sets the stage for the seamless progression of the shed roof framing project, bringing you closer to the realization of a functional and visually appealing outdoor space.

Step 4: Add Roof Sheathing

With the trusses securely in place, the next pivotal phase in the shed roof framing process involves the addition of roof sheathing. Roof sheathing serves as the foundational layer that provides structural support for the roofing material while contributing to the overall stability and integrity of the roof.

Selecting the Sheathing Material

Before proceeding with the installation of roof sheathing, it's essential to choose the appropriate material based on the specific requirements of your shed. Plywood and oriented strand board (OSB) are commonly used for roof sheathing due to their strength, durability, and suitability for load-bearing applications. Consider the local climate and potential exposure to moisture when selecting the sheathing material, ensuring that it can withstand the elements and provide reliable protection for the shed.

Read more: How To Build A Shed Roof

Measuring and Cutting

Begin by measuring the dimensions of the roof surface to determine the precise area to be covered by the sheathing. Carefully mark the sheathing material based on these measurements, ensuring accuracy and minimal waste during the cutting process. Utilize a circular saw to cut the sheathing panels to the required dimensions, taking care to achieve clean and straight cuts that align with the edges of the roof.

Installation Process

With the sheathing panels prepared, position the first panel at one edge of the roof, ensuring that it aligns with the truss edges and overhang, if applicable. Secure the panel in place using appropriate fasteners, such as nails or screws, driving them into the trusses below. Subsequent panels should be installed in a staggered pattern, with their edges overlapping to provide continuous coverage and enhance the structural integrity of the roof.

Ensuring Stability and Alignment

As each sheathing panel is installed, verify that it lies flat and aligns seamlessly with the adjacent panels, minimizing any gaps or unevenness. Utilize a level to confirm that the sheathing maintains a consistent plane across the roof surface, promoting uniform support for the roofing material. Additionally, ensure that the sheathing extends slightly beyond the edges of the roof to facilitate proper flashing and weatherproofing.

Finalizing the Sheathing

Upon completing the installation of the roof sheathing, inspect the entire surface to confirm that it is securely fastened and free from any protruding fastener heads. Address any loose panels or irregularities to guarantee a solid and reliable foundation for the subsequent installation of the chosen roofing material. With the roof sheathing in place, the shed's roof structure gains essential strength and resilience, setting the stage for the final phase of adding the selected roofing material.

By meticulously adding roof sheathing to the shed, you fortify the roof structure with a sturdy and dependable foundation, ensuring long-term durability and weather resistance. This critical step brings you closer to the completion of the shed roof framing project, paving the way for the installation of the final roofing material to safeguard the shed against the elements.

Step 5: Install Roofing Material

With the roof sheathing securely in place, the focus now shifts to the pivotal phase of installing the roofing material, a crucial step in completing the shed roof framing process. The choice of roofing material plays a significant role in not only providing weatherproofing and protection but also contributing to the overall aesthetic appeal of the shed.

Selecting the Roofing Material

The selection of the roofing material is influenced by various factors, including the shed's design, local climate, and personal preferences. Asphalt shingles, known for their affordability and ease of installation, are a popular choice for shed roofs. They are available in a variety of colors and styles, allowing for customization to complement the overall design of the shed. Alternatively, metal roofing panels offer exceptional durability and longevity, making them suitable for sheds in regions prone to harsh weather conditions.

Preparing for Installation

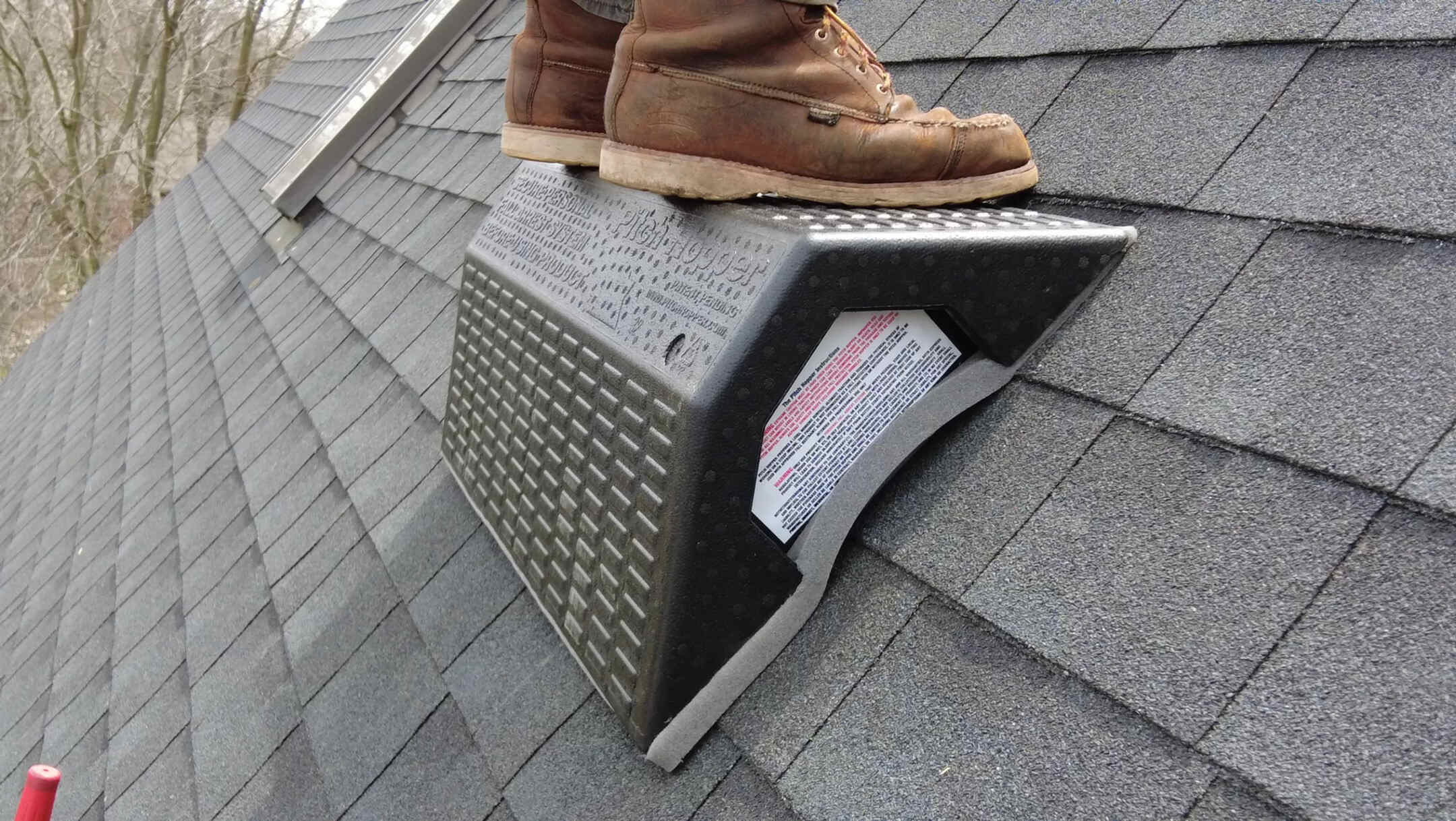

Before commencing the installation of the roofing material, ensure that the roof surface is clean, dry, and free from any debris or protruding fasteners. Additionally, inspect the sheathing for any irregularities or damage that may affect the integrity of the roofing installation. It's essential to have the necessary safety equipment, such as harnesses and non-slip footwear, to ensure a secure working environment during the installation process.

Application of Roofing Material

Begin the installation process by positioning the first course of roofing material at the bottom edge of the roof, aligning it meticulously to ensure a straight and uniform appearance. Secure the roofing material using appropriate fasteners, following the manufacturer's guidelines for the recommended placement and spacing. As each subsequent course is added, overlap the edges to create a watertight barrier that prevents moisture infiltration and enhances the shed's resilience against the elements.

Finishing Touches

As the roofing material nears the ridgeline of the shed, attention to detail becomes paramount. Carefully trim the roofing material to fit the contours of the roof, ensuring a seamless and professional finish. Additionally, install ridge caps or appropriate ridge venting to provide ventilation and protect the ridgeline from potential water penetration. These finishing touches not only contribute to the functionality of the roof but also elevate its visual appeal.

Ensuring Quality and Longevity

Throughout the installation of the roofing material, prioritize precision and attention to detail to guarantee a high-quality and long-lasting result. Regularly inspect the installed material for uniformity, secure fastenings, and proper alignment to address any issues promptly. By adhering to best practices and manufacturer recommendations, you can ensure that the shed's roof is fortified with a reliable and resilient covering that will withstand the test of time.

By meticulously installing the chosen roofing material, you bring the shed roof framing project to its culmination, achieving a functional and visually appealing roof that provides essential protection and enhances the overall aesthetic of the shed. With the roofing material in place, the shed is poised to stand as a durable and reliable structure, ready to weather the elements for years to come.

Step 6: Add Overhang to the Roof

As the shed roof framing nears completion, the addition of an overhang serves as the final touch that not only enhances the functionality of the roof but also elevates its visual appeal. An overhang extends beyond the edge of the roof, providing shelter from the elements and adding a touch of architectural elegance to the shed. This essential feature offers protection against rain, snow, and harsh sunlight, creating a more comfortable outdoor space while contributing to the overall design aesthetic.

Planning the Overhang

Before proceeding with the construction of the overhang, careful planning is essential to determine the desired length and width of the extension. Consider the functional aspects of the overhang, such as the degree of protection it will offer and its compatibility with the shed's design. Additionally, evaluate the local climate to ensure that the overhang is tailored to withstand prevailing weather conditions effectively.

Read more: How to Build Aluminum Storm Window Frames

Framing the Overhang

To begin the construction of the overhang, extend the roof rafters beyond the walls of the shed to the specified length, accounting for the desired overhang distance. Secure the extended rafters with additional bracing to ensure structural stability and resistance to external forces. Subsequently, install the soffit material on the underside of the overhang to enclose the space and create a polished appearance.

Functional and Aesthetic Benefits

The overhang not only shields the shed's walls and foundation from moisture but also provides a shaded area that can be utilized for various outdoor activities. Whether it's creating a cozy seating area or protecting stored items from the elements, the overhang adds versatility to the shed's functionality. Furthermore, from an aesthetic standpoint, the overhang contributes to the architectural charm of the shed, imparting a sense of refinement and completeness to the overall design.

Weatherproofing and Finishing

To ensure that the overhang effectively repels water and maintains its structural integrity, it's essential to apply appropriate flashing and sealant at the junction between the overhang and the main roof. This step prevents water infiltration and reinforces the overhang's resistance to moisture. Additionally, consider incorporating decorative elements, such as corbels or trim, to accentuate the visual appeal of the overhang and harmonize it with the shed's design.

By adding an overhang to the shed roof, you not only enhance the functionality and weather resistance of the structure but also infuse it with a touch of sophistication and practicality. This final phase of the shed roof framing process culminates in the creation of a well-appointed and resilient outdoor space, ready to serve its intended purposes while exuding timeless charm and durability.

Conclusion

In conclusion, the process of framing a shed roof with an overhang encompasses a series of meticulous steps that culminate in the creation of a durable, functional, and visually appealing structure. From the initial measurements and marking of the shed to the installation of the roofing material and the addition of the overhang, each phase plays a crucial role in shaping the overall integrity and aesthetic of the shed.

By meticulously measuring and marking the shed, the foundation is laid for the precise construction of roof trusses and the seamless integration of the overhang. The careful selection of materials and tools, combined with a keen eye for detail, ensures that the subsequent phases of the project proceed with efficiency and precision.

The process of cutting and assembling the roof trusses represents a pivotal stage in the shed roof framing journey. The structural framework provided by the trusses forms the backbone of the roof, offering essential support and stability. Attention to detail during the truss construction phase is paramount, as it directly impacts the structural integrity and load-bearing capacity of the roof.

The installation of the trusses on the shed marks a significant stride in the project, bringing the roof structure to life and setting the stage for the addition of roof sheathing. The meticulous application of roof sheathing provides a solid foundation for the roofing material, ensuring structural support and weather resistance.

The installation of the chosen roofing material represents the culmination of the shed roof framing process, providing essential protection and visual appeal. Whether opting for asphalt shingles or metal roofing panels, the careful application of the roofing material enhances the shed's resilience and elevates its overall aesthetic.

Finally, the addition of an overhang serves as the crowning touch, offering shelter from the elements and infusing the shed with architectural elegance. The overhang not only enhances the functionality of the roof but also contributes to the shed's visual appeal, creating a versatile and refined outdoor space.

In essence, the process of framing a shed roof with an overhang is a testament to the meticulous craftsmanship and attention to detail required to create a structure that seamlessly blends functionality, durability, and timeless charm. By following this comprehensive guide, DIY enthusiasts and novice builders alike can embark on their shed roof framing journey with confidence, knowing that each step contributes to the creation of a resilient and visually captivating outdoor space.