Home>Home & Furniture>Roof>How to Build DIY Roof Platforms for Pitched Roofing

Roof

How to Build DIY Roof Platforms for Pitched Roofing

Published: August 21, 2024

Learn how to build DIY roof platforms for pitched roofing with our step-by-step guide. Ensure safety and efficiency in your roofing projects with these expert tips and techniques.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Twigandthistle.com, at no extra cost. Learn more)

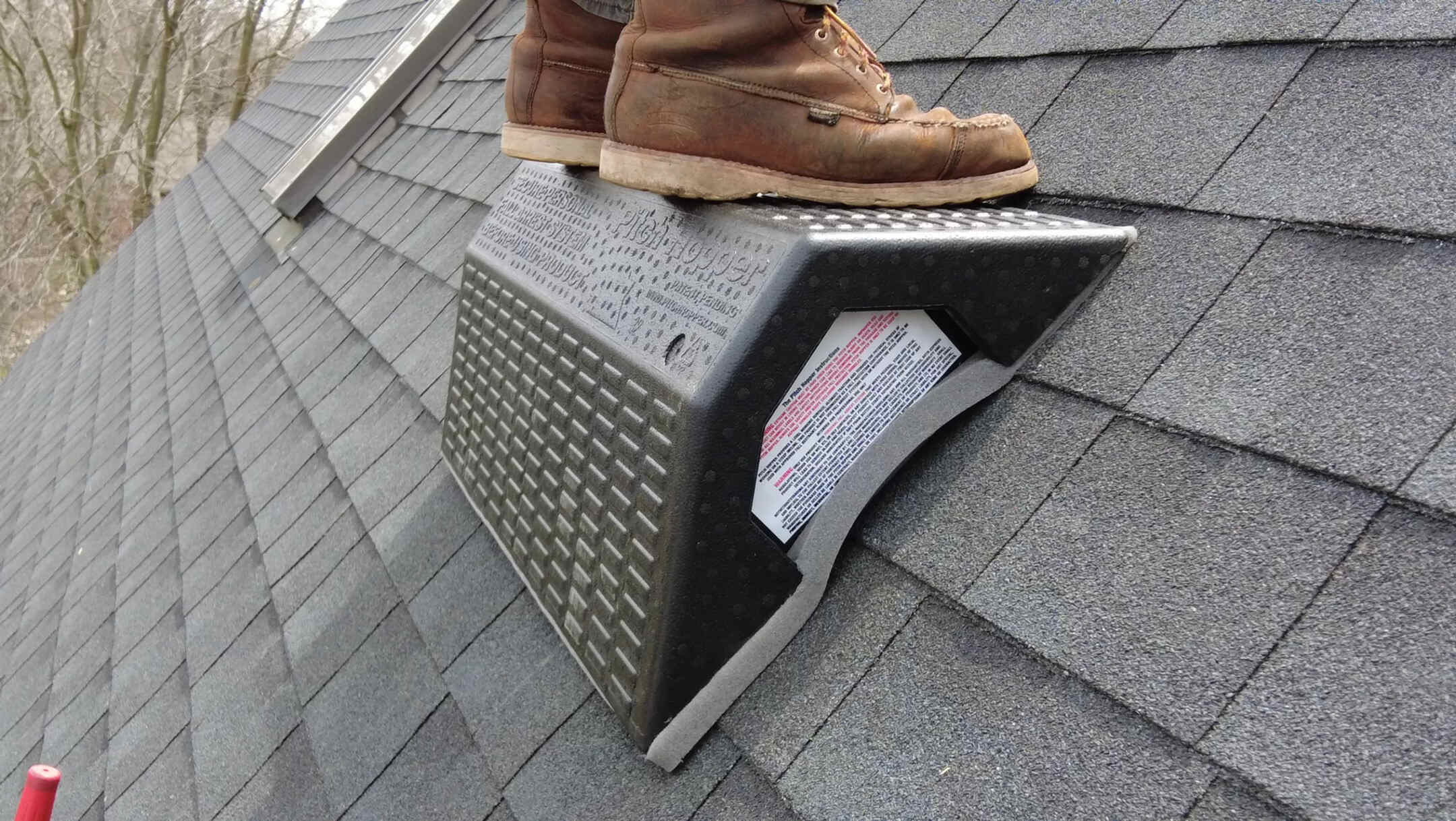

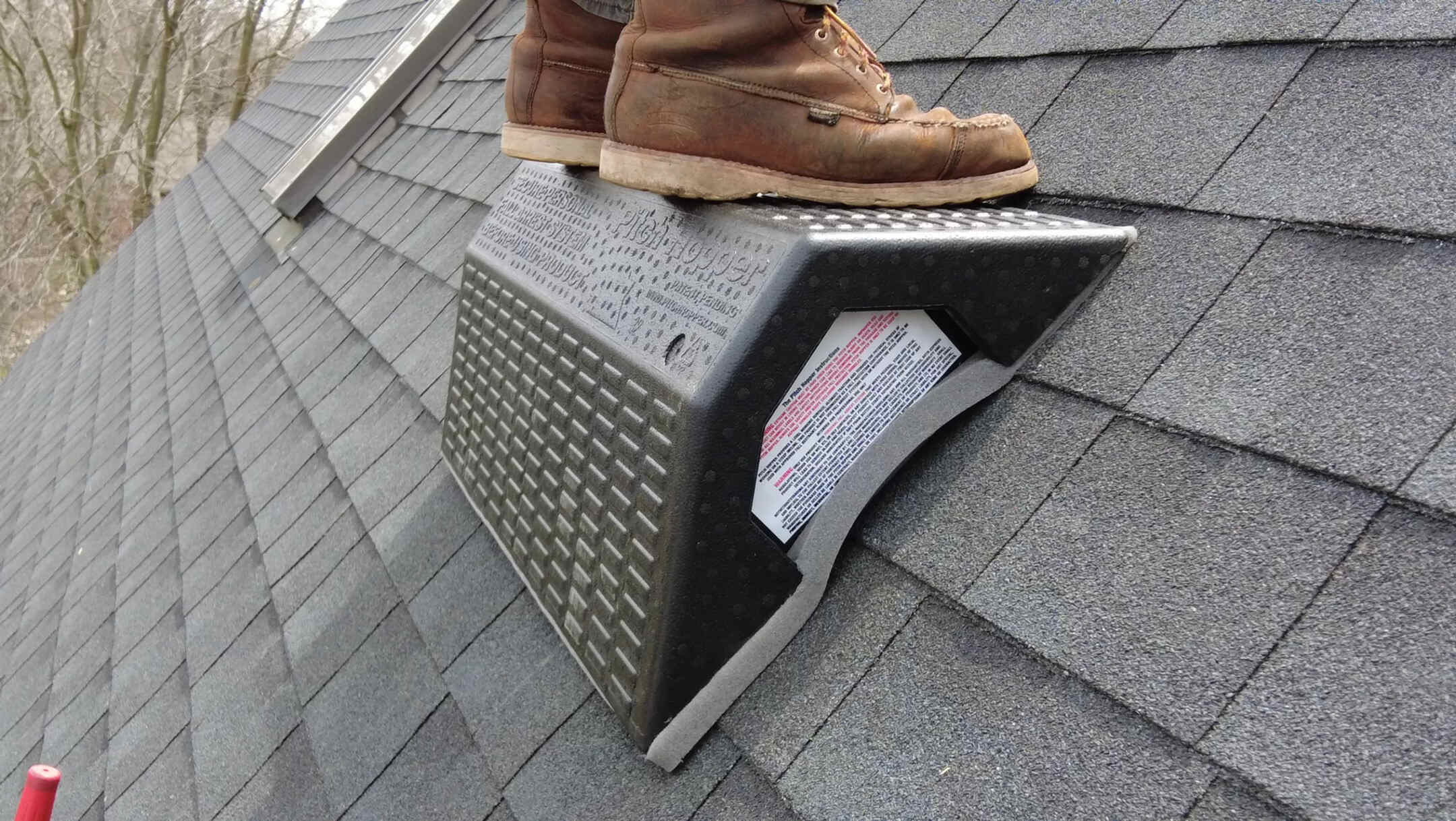

Working on pitched roofs can be tricky and dangerous without the right tools. Building a DIY roof platform provides a stable area, making the task safer and easier. This guide will help you understand how to construct your own roof platform using simple materials and tools. Even if you're a beginner, don't worry—you'll find the process straightforward with our step-by-step instructions. Whether you're planning to fix shingles, clean gutters, or install a skylight, a sturdy platform is essential for any rooftop job. Let's get started on creating a safe work surface for your next roofing project.

Getting Ready for Your Project

Gather Materials: Collect all necessary tools and materials like plywood, screws, nails, a hammer, a saw, and safety gear.

Safety Gear: Wear non-slip shoes, a hard hat, gloves, and a safety harness. Ensure your harness is securely attached to a stable anchor point.

Inspect the Roof: Check for any damage or weak spots. Repair any issues before starting the project.

Clear the Area: Remove any debris, leaves, or loose shingles from the roof to prevent slipping.

Measure and Mark: Measure the area where the platform will be built. Mark the dimensions on the roof using chalk.

Cut Plywood: Use a saw to cut the plywood to the required size. Make sure the cuts are straight and smooth.

Set Up a Stable Ladder: Position a sturdy ladder on a flat surface. Ensure it reaches the roof comfortably and is securely placed.

Prepare the Workspace: Lay out all tools and materials within easy reach. Keep the workspace organized to avoid accidents.

Weather Check: Ensure the weather is clear. Avoid working on the roof during rain, snow, or high winds.

Buddy System: Have someone assist you. They can hand you tools, hold the ladder, or call for help if needed.

Materials and Tools Needed

- Plywood Sheets: Strong, flat boards used as the base of the platform.

- 2x4 Lumber: Wooden beams for framing and support.

- Screws: Metal fasteners to hold the wood together.

- Nails: Used for additional fastening and support.

- Hammer: Tool for driving nails into wood.

- Screwdriver: Tool for driving screws into wood.

- Circular Saw: Electric saw for cutting wood to size.

- Measuring Tape: Tool for measuring lengths accurately.

- Level: Ensures the platform is even and balanced.

- Safety Gear: Includes gloves, goggles, and a hard hat for protection.

- Ladder: Provides access to the roof.

- Chalk Line: Marks straight lines on wood for cutting.

- Drill: Electric tool for making holes and driving screws.

- Carpenter's Square: Ensures right angles in your cuts and assembly.

- Clamps: Hold pieces of wood together while working.

These materials and tools will help you build a sturdy, safe platform for working on a pitched roof.

Skill Level and Time Required

Skill Level: Advanced

Time Required: 10-12 hours

Steps:

- Gather Materials: 1 hour

- Measure and Cut Wood: 2 hours

- Assemble Platform Base: 3 hours

- Install Safety Rails: 2 hours

- Secure Platform to Roof: 2-4 hours

Step-by-Step Instructions

Gather Materials and Tools

- Plywood sheets

- 2x4 lumber

- Nails or screws

- Hammer or drill

- Measuring tape

- Saw

- Safety gear (gloves, goggles, harness)

Measure the Roof

- Use measuring tape to determine the dimensions of the roof area where the platform will be placed.

- Note the pitch angle of the roof.

Cut the Plywood and Lumber

- Cut plywood sheets to the desired size for the platform.

- Cut 2x4 lumber to create the frame and supports.

Assemble the Frame

- Lay out the 2x4 pieces to form a rectangular frame.

- Secure the corners with nails or screws.

Attach Plywood to Frame

- Place the cut plywood on top of the frame.

- Secure the plywood to the frame using nails or screws.

Add Supports

- Cut additional 2x4 pieces to act as supports under the platform.

- Attach these supports at regular intervals to ensure stability.

Install Safety Features

- Attach guardrails or safety barriers around the platform edges.

- Ensure all safety features are securely fastened.

Position the Platform

- Carefully lift the platform onto the roof.

- Secure the platform to the roof using nails or screws, ensuring it is stable and level.

Test Stability

- Gently apply pressure to different areas of the platform to check for stability.

- Make any necessary adjustments to ensure the platform is secure.

Use Safety Gear

- Always wear gloves, goggles, and a harness when working on the roof.

- Ensure all safety gear is properly fitted and secure before starting work.

Tips and Tricks

Measure the roof's pitch accurately. Use a digital level or pitch gauge.

Secure the platform with strong brackets and screws. Avoid using nails; they can loosen over time.

Use pressure-treated wood for durability. Plywood works well for the platform surface.

Wear safety gear: harness, non-slip shoes, and gloves. Always have a spotter.

Common mistakes to avoid:

- Skipping the measuring step.

- Using weak materials.

- Ignoring safety precautions.

Alternatives:

- Metal platforms for longer-lasting solutions.

- Modular scaffolding if you need to move the platform frequently.

Cost Estimation

Materials:

- Plywood Sheets: $20 each (4 needed) = $80

- 2x4 Lumber: $3 per piece (10 needed) = $30

- Deck Screws: $10 per box (1 box) = $10

- Metal Brackets: $1 each (20 needed) = $20

- Safety Harness: $50

- Roofing Nails: $5 per box (1 box) = $5

Tools:

- Circular Saw: $50

- Drill: $40

- Hammer: $10

- Measuring Tape: $5

- Level: $10

Total Cost: $310

Budget-Friendly Alternatives:

- Plywood Sheets: Use reclaimed wood or pallets (often free or cheaper)

- 2x4 Lumber: Look for used or discounted lumber at local stores

- Deck Screws: Buy in bulk to save money

- Safety Harness: Rent from a local hardware store instead of buying

- Circular Saw and Drill: Borrow from friends or rent from a tool library

Variations and Customizations

Materials: Instead of using wood, consider metal or composite decking for the platform. Metal offers durability, while composite decking resists weather damage.

Colors: Paint or stain the wood to match your house's exterior. Use weather-resistant paint in colors like gray, brown, or white. For metal platforms, powder-coating in various colors can add a sleek look.

Styles: Customize the platform's design. Add railings for safety, or integrate storage compartments for tools. Use decorative brackets or trim to enhance the aesthetic.

Alternative Designs: Create a modular platform that can be easily assembled and disassembled. This makes storage and transport simpler. Another option is a foldable platform for compact storage.

Surface Options: Cover the platform with non-slip mats or rubber tiles for added safety. These materials provide better grip and reduce the risk of slipping.

Height Adjustments: Design the platform with adjustable legs to accommodate different roof pitches. This ensures stability on various surfaces.

Weather Protection: Add a canopy or awning to shield the platform from rain and sun. This extends the platform's lifespan and provides comfort while working.

Lighting: Install solar-powered lights on the platform for better visibility during early morning or late evening work. This enhances safety and convenience.

Tool Holders: Attach hooks or magnetic strips to the platform's sides for easy access to tools. This keeps your workspace organized and efficient.

Safety Features: Incorporate safety harness anchors into the platform design. This provides an extra layer of protection when working on steep roofs.

Sustainability Tips

Reclaimed wood can be used for the platform base. It’s sturdy and reduces waste. Bamboo is another great option. It’s strong, lightweight, and grows quickly, making it very sustainable.

For the support beams, consider recycled metal. It’s durable and can often be found at salvage yards. Composite decking made from recycled plastics and wood fibers is also a good choice. It’s weather-resistant and long-lasting.

Use eco-friendly paint or sealant to protect the wood. Look for products with low VOCs (volatile organic compounds) to minimize harmful emissions.

When assembling, opt for screws and nails made from recycled materials. They’re just as strong and help reduce the demand for new metal production.

For added safety, install recycled rubber mats on the platform. They provide good traction and are made from old tires, keeping them out of landfills.

Lastly, if you need to use a ladder, consider borrowing or renting one instead of buying new. This reduces the need for new resources and saves money.

Your Roof, Your Rules

Building DIY roof platforms for pitched roofing isn't just a money-saver; it's a confidence booster. You’ve learned how to measure, cut, and assemble materials, turning a daunting task into a manageable project. With safety gear and a steady hand, you’ve tackled something many shy away from. Remember, the key is preparation and patience. Each step, from planning to execution, adds to your skill set. Now, you can look at your roof and say, "I did that." Keep these tips handy for future projects. Who knows? Maybe next time, you’ll be building a shed or deck. The sky's the limit when you’ve got the right tools and a bit of know-how. So, grab your toolbox and get ready for your next DIY adventure. Happy building!

How do I ensure my DIY roof platform is safe?

Use sturdy materials like treated lumber and secure all joints with screws or bolts. Double-check the platform's stability before climbing on it.

What tools will I need to build a roof platform?

You'll need a saw, drill, measuring tape, level, screws or bolts, and safety gear like gloves and a harness.

Can I build a roof platform by myself?

It's possible, but having a helper makes it safer and easier. Two sets of hands can better manage materials and ensure stability.

How do I attach the platform to a pitched roof?

Use roof brackets or hooks designed for pitched roofs. Secure them firmly to the roof structure to prevent slipping.

What size should my roof platform be?

The size depends on your needs, but a common size is around 4 feet by 8 feet. Ensure it's large enough to work comfortably but not too heavy.

How do I protect my roof from damage while building the platform?

Place protective padding or rubber mats under the platform supports. This helps distribute weight and prevents damage to shingles.

Can I leave the platform on the roof permanently?

It's not recommended. Temporary platforms are safer and less likely to cause long-term damage to your roof.