Home>Home & Furniture>Doors & Windows>DIY Window Screen Kit: How to Build Your Own

Doors & Windows

DIY Window Screen Kit: How to Build Your Own

Published: August 20, 2024

Learn how to build your own window screen with a DIY kit. Our step-by-step guide makes it easy to create custom screens for your home. Perfect for beginners!

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Twigandthistle.com, at no extra cost. Learn more)

Looking to keep bugs out while letting fresh air in? Building your own window screen is easier than you think. Buying a DIY window screen kit can save you money and fit perfectly to your window's measurements. You'll only need a few tools and some patience. Customizing your window screen not only keeps pests away but can also be a fun weekend project. Whether you’re new to DIY or have some experience, assembling a window screen can be accomplished in an afternoon. Ready to get started? Let’s dive into the basics of building your very own window screen.

Getting Ready for Your Project

- Gather Materials: Get a window screen kit, spline roller, utility knife, and measuring tape.

- Measure Window Frame: Measure the width and height of the window frame to ensure the screen fits perfectly.

- Cut Frame Pieces: Use a hacksaw to cut the frame pieces to the measured dimensions.

- Assemble Frame: Connect the frame pieces using the corner connectors provided in the kit.

- Prepare Workspace: Set up a clean, flat surface to work on. Ensure good lighting and ventilation.

- Safety Gear: Wear safety gloves and goggles to protect your hands and eyes.

- Lay Out Screen Material: Roll out the screen material over the assembled frame, leaving extra on all sides.

- Insert Spline: Use the spline roller to press the spline into the groove, securing the screen material.

- Trim Excess Screen: Carefully trim the excess screen material with a utility knife.

- Check for Tension: Ensure the screen is taut and free of wrinkles or sagging.

What You Need: Materials and Tools

Materials:

- Screen Frame Kit: Contains the aluminum frame pieces that form the border of the screen.

- Screen Mesh: The material that keeps bugs out while allowing airflow.

- Spline: A rubber cord that holds the screen mesh in place within the frame.

- Corner Connectors: Plastic or metal pieces that join the frame pieces at the corners.

- Pull Tabs: Small tabs that make it easier to remove the screen from the window.

Tools:

- Spline Roller: A tool with a wheel used to press the spline into the frame.

- Utility Knife: For cutting the screen mesh to size.

- Measuring Tape: Ensures accurate measurements of the window and screen frame.

- Scissors: Useful for trimming excess screen mesh.

- Flathead Screwdriver: Helps in pushing the spline into tight corners.

- Rubber Mallet: Gently taps the frame pieces together without damaging them.

Screen Frame Kit pieces form the border of the screen. Screen Mesh keeps bugs out while allowing airflow. Spline holds the screen mesh in place within the frame. Corner Connectors join the frame pieces at the corners. Pull Tabs make it easier to remove the screen from the window.

Spline Roller presses the spline into the frame. Utility Knife cuts the screen mesh to size. Measuring Tape ensures accurate measurements. Scissors trim excess screen mesh. Flathead Screwdriver pushes the spline into tight corners. Rubber Mallet taps the frame pieces together without damaging them.

How Much Time and Skill Is Needed?

Skill Level: Beginner

Time Required: 1-2 hours

- Measure the Window Frame: 10-15 minutes

- Cut the Frame Pieces: 15-20 minutes

- Assemble the Frame: 20-30 minutes

- Attach the Screen: 20-30 minutes

- Install the Screen: 10-15 minutes

Follow These Steps to Build Your Screen

Gather Materials:

- Window screen kit

- Screen mesh

- Spline (rubber cord)

- Spline roller

- Scissors

- Utility knife

- Measuring tape

Measure the Window:

- Use the measuring tape to find the width and height of the window frame.

- Write down the measurements.

Cut the Frame Pieces:

- Use the measurements to cut the frame pieces from the kit.

- Make sure to cut at 45-degree angles for corners.

Assemble the Frame:

- Connect the frame pieces using the corner connectors.

- Ensure the frame is square and fits the window opening.

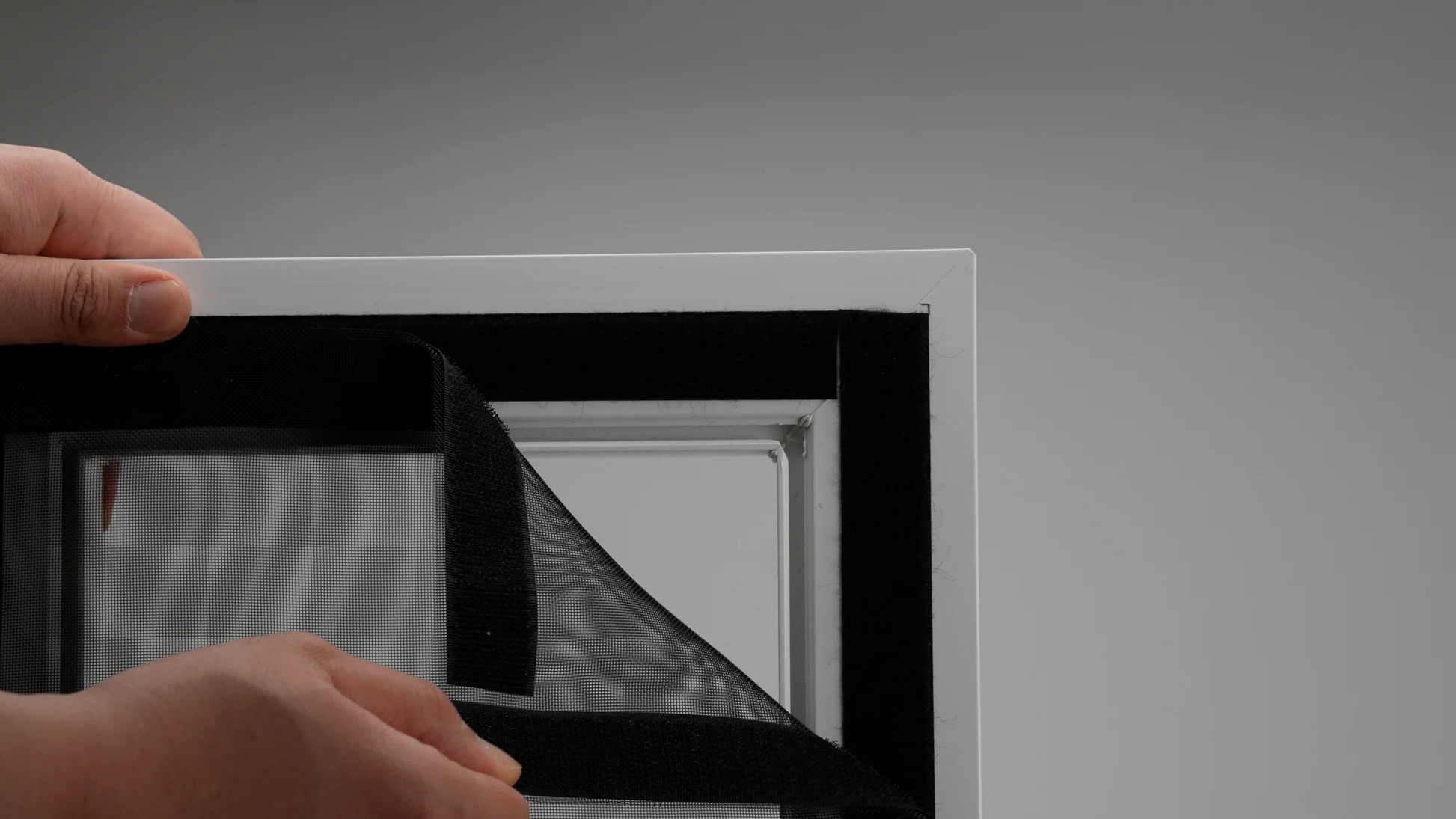

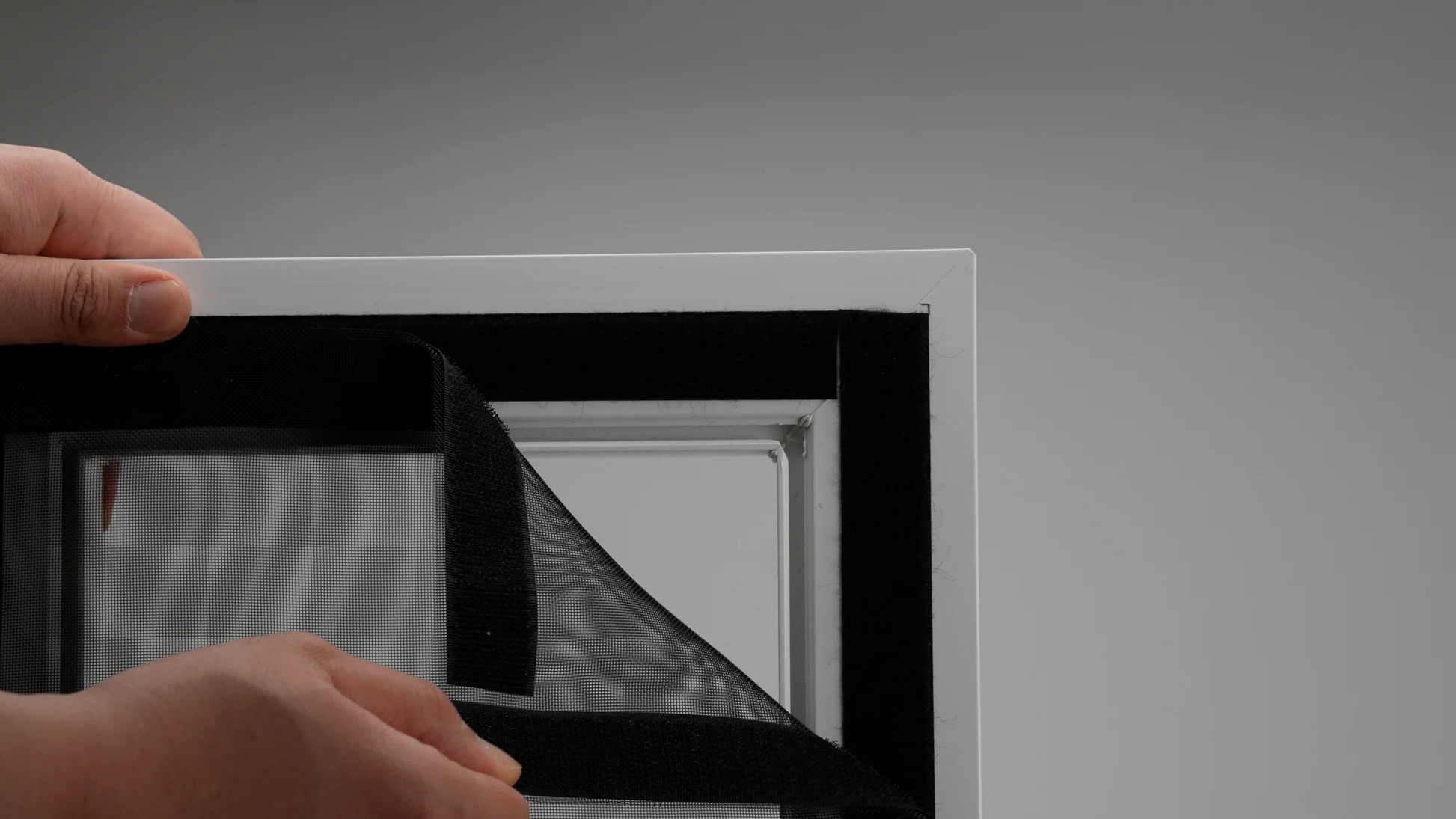

Lay Out the Screen Mesh:

- Place the assembled frame on a flat surface.

- Lay the screen mesh over the frame, leaving extra mesh around the edges.

Cut the Screen Mesh:

- Use scissors to cut the mesh, leaving about 2 inches of extra mesh around the frame.

Insert the Spline:

- Use the spline roller to press the spline into the groove of the frame.

- Start at one corner and work your way around, pulling the mesh tight.

Trim Excess Mesh:

- Use the utility knife to trim the extra mesh along the outside edge of the spline.

Install the Screen:

- Place the finished screen into the window frame.

- Secure it with any clips or fasteners provided in the kit.

Check for Fit:

- Ensure the screen fits snugly and there are no gaps.

Helpful Tips and Tricks

Measure your window frame accurately. Use a tape measure to get the exact dimensions. Cut the screen frame pieces to fit your measurements. Use a miter box for precise cuts.

When assembling the frame, use corner connectors to ensure stability. Make sure the frame is square by measuring diagonally from corner to corner. Both measurements should be equal.

Lay the screen mesh over the frame. Cut the mesh with a utility knife, leaving an extra inch around the edges. Use a spline roller to press the spline into the groove, securing the mesh. Start at one corner and work your way around.

Trim any excess mesh with the utility knife. Check for any loose spots and re-roll the spline if needed.

Common mistakes to avoid include cutting the frame pieces too short, not securing the mesh tightly, and using the wrong type of spline. Always double-check measurements before cutting.

For materials, consider using fiberglass mesh instead of aluminum. Fiberglass is easier to work with and more durable. If you don't have a spline roller, a flathead screwdriver can work in a pinch.

How Much Will This Cost?

Materials:

- Screen Mesh: $10-$15 for a roll (enough for 2-3 windows)

- Screen Frame Kit: $12-$20 per window

- Spline: $3-$5 for a roll (enough for multiple windows)

- Spline Roller: $5-$10

- Corner Connectors: Usually included in the frame kit, but extra ones cost $2-$5 for a pack

Tools:

- Utility Knife: $5-$10

- Measuring Tape: $5-$10

- Scissors: $5-$10

Total Cost: $42-$85 for one window, depending on the quality of materials and tools chosen.

Budget-Friendly Alternatives:

- Screen Mesh: Use fiberglass mesh instead of aluminum to save $5-$10.

- Spline Roller: Use a flathead screwdriver instead, saving $5-$10.

- Utility Knife: Use scissors for cutting the mesh, saving $5-$10.

Different Ways to Customize Your Screen

Frame Materials: Instead of standard aluminum, try wood for a rustic look or PVC for a lightweight, durable option.

Screen Types: Use fiberglass for flexibility, metal mesh for durability, or pet-resistant screens if you have pets.

Colors: Paint frames in white for a clean look, black for a modern touch, or natural wood stain for a classic feel.

Styles: Opt for decorative trim on the frame edges, or add a crossbar for extra support and style.

Fasteners: Use magnetic strips for easy removal, hinges for a swing-out design, or velcro for a simple, no-tools-needed option.

Handles: Attach pull tabs for easy lifting, or install small handles for a more permanent grip.

Weatherproofing: Add weatherstripping around the edges to keep out drafts, or use silicone sealant for a tighter fit.

Insect Protection: Choose fine mesh to keep out tiny bugs, or standard mesh for general use.

Decorative Elements: Add stenciled designs on the screen for a personalized touch, or use colored mesh for a unique look.

Size Adjustments: Customize the frame size to fit odd-shaped windows or large openings.

Eco-Friendly Tips for Your Project

Bamboo frames are a great eco-friendly option. Bamboo grows quickly and is very strong. Reclaimed wood can also be used for the frame. Look for old furniture or pallets to repurpose.

For the screen material, consider using recycled polyester mesh. This type of mesh is made from recycled plastic bottles. It’s durable and helps reduce plastic waste.

Use natural oils like linseed oil to finish the wood. These oils are less harmful to the environment compared to synthetic finishes.

When attaching the screen to the frame, opt for stainless steel staples or tacks. Stainless steel is more durable and can be recycled.

For the spline, which holds the screen in place, consider using natural rubber instead of synthetic rubber. Natural rubber is biodegradable and comes from renewable sources.

If you need to replace an old screen, try to reuse the existing frame. Just remove the old mesh and replace it with new, eco-friendly material.

Lastly, use hand tools instead of power tools whenever possible. Hand tools use no electricity and reduce your carbon footprint.

Your DIY Window Screen Awaits

Building your own window screen isn't just cost-effective, it's also super satisfying. You've learned how to measure, cut, and assemble the frame, then attach the screen material. Now, you can enjoy a bug-free home with fresh air flowing in. Plus, you’ve got the skills to tackle other DIY projects around the house. Remember, practice makes perfect. If your first screen isn't flawless, don't sweat it. Each attempt will get better. Keep your tools handy, and don’t hesitate to experiment with different materials or techniques. Your home improvement journey has just begun. So, grab that screen kit, roll up your sleeves, and get to work. You’ve got this!

What tools do I need to build a window screen kit?

You'll need a measuring tape, utility knife, spline roller, and a screwdriver. Having a rubber mallet can also help.

How do I measure my window for the screen?

Measure the width and height of the window frame. Subtract about 1/8 inch from each measurement to ensure the screen fits snugly.

What materials are included in a window screen kit?

Most kits come with screen mesh, frame pieces, corners, and spline. Some might also include a spline roller.

Can I choose the type of screen mesh?

Yes, you can pick from fiberglass, aluminum, or pet-resistant mesh. Each type has its own benefits.

How do I assemble the frame?

Connect the frame pieces using the corners provided. Make sure they're tightly fitted before adding the mesh.

How do I attach the screen mesh to the frame?

Lay the mesh over the frame, then use the spline roller to press the spline into the groove, securing the mesh.

What if my screen gets damaged?

You can replace the mesh by removing the old spline and mesh, then installing new mesh using the same steps.