Home>Home & Furniture>Doors & Windows>Step-by-step guide to installing plexiglass

Doors & Windows

Step-by-step guide to installing plexiglass

Published: August 16, 2024

Learn how to install plexiglass with our step-by-step guide. From measuring and cutting to securing and finishing, get expert tips for a flawless installation.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Twigandthistle.com, at no extra cost. Learn more)

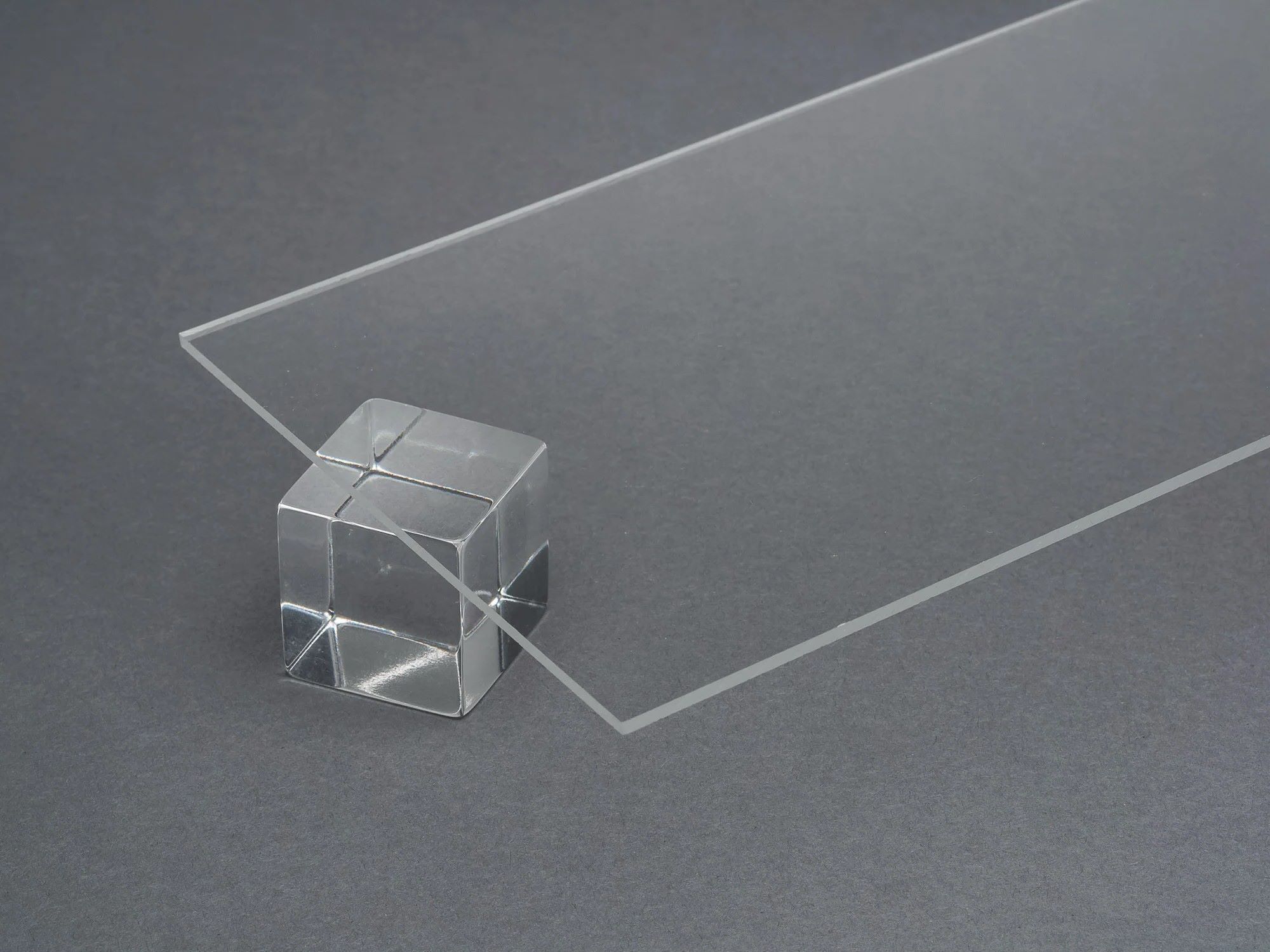

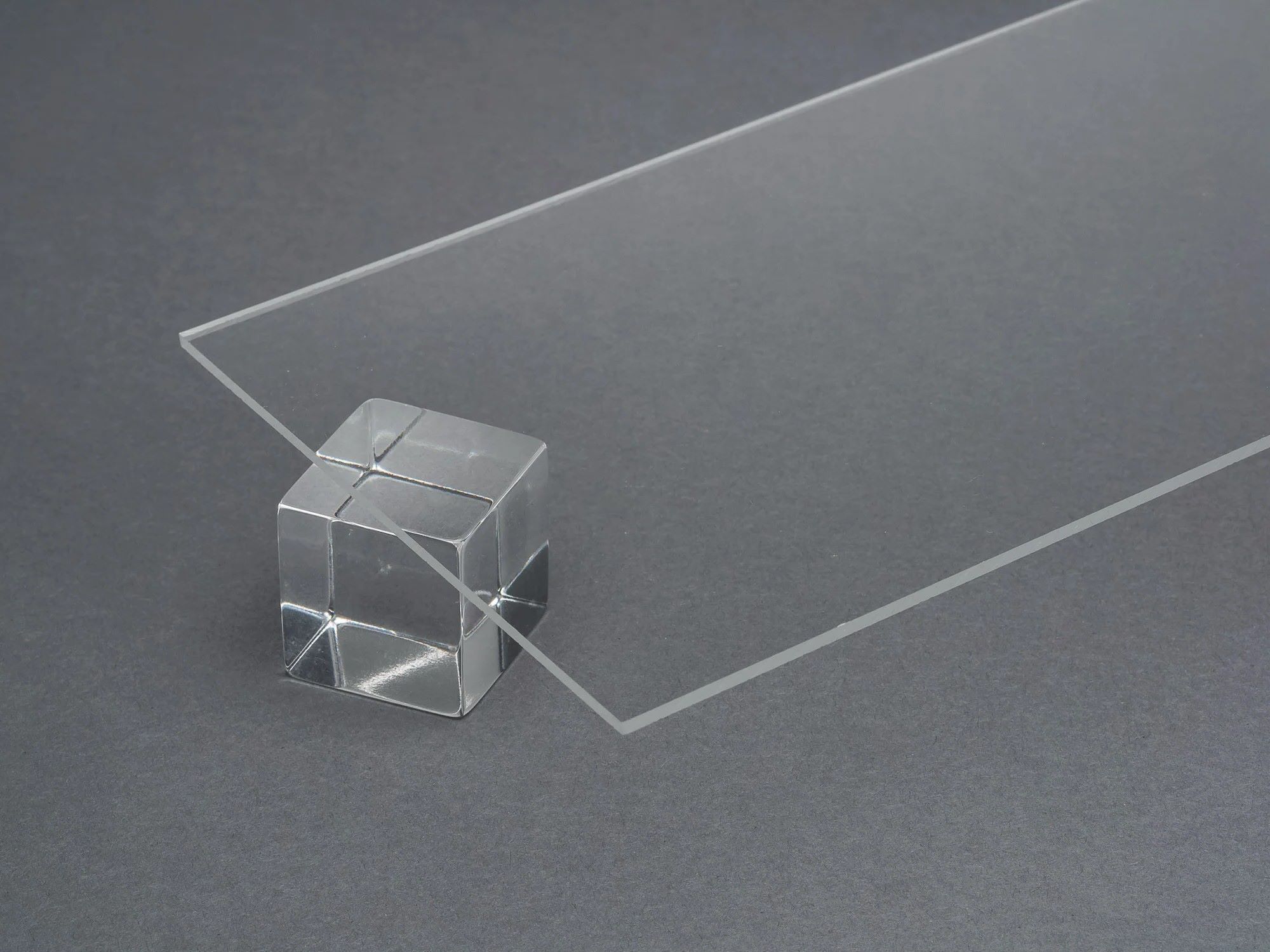

Plexiglass is a versatile material often used in DIY projects around the home. Installing it might seem tricky, but with a few basic tools and a bit of patience, anyone can do it. Whether you need it for windows, a protective barrier, or craft projects, plexiglass offers durability and clarity. This guide will walk you through each step, ensuring a smooth installation process. No need to hire a professional when you can tackle this project yourself. Roll up your sleeves and get ready to add a sleek touch to your space. Let's get started!

Getting Ready for the Project

Measure the Area: Use a tape measure to get the exact dimensions of the space where the plexiglass will go. Write down these measurements.

Gather Tools and Materials: Collect a tape measure, marker, safety goggles, gloves, a saw (preferably a jigsaw), sandpaper, and screws or adhesive.

Safety First: Wear safety goggles and gloves to protect your eyes and hands from shards and sharp edges.

Prepare the Workspace: Clear a flat, stable surface to work on. Ensure good lighting and ventilation.

Mark the Plexiglass: Use a marker to outline the measurements on the plexiglass sheet. Double-check for accuracy.

Cut the Plexiglass: Secure the plexiglass on the work surface. Use a saw to cut along the marked lines. Go slowly to avoid cracking.

Smooth the Edges: Sand the cut edges with sandpaper to remove any rough spots or sharp edges.

Clean the Surface: Wipe down the plexiglass with a damp cloth to remove dust and debris.

Drill Holes (if needed): If screws will be used, mark and drill holes in the plexiglass. Use a drill bit designed for plastic.

Install the Plexiglass: Position the plexiglass in place. Secure it with screws or adhesive, depending on your project needs.

Final Check: Ensure the plexiglass is securely installed and there are no gaps or loose edges.

Gather Your Materials and Tools

- Plexiglass Sheets: Clear or colored plastic sheets used as a substitute for glass.

- Measuring Tape: Tool for measuring the dimensions of the area where the plexiglass will be installed.

- Marker: Used to mark cutting lines on the plexiglass.

- Straight Edge: Helps in drawing straight lines for accurate cuts.

- Utility Knife: Cuts through thinner plexiglass sheets.

- Jigsaw: For cutting thicker plexiglass sheets.

- Drill: Creates holes in the plexiglass for screws or bolts.

- Drill Bits: Attachments for the drill, sized according to the screws or bolts.

- Sandpaper: Smooths the edges of the cut plexiglass.

- Clamps: Holds the plexiglass in place while cutting or drilling.

- Safety Glasses: Protects eyes from flying debris during cutting or drilling.

- Gloves: Protects hands from sharp edges and tools.

- Screws or Bolts: Secures the plexiglass to the frame or surface.

- Screwdriver: Tightens screws or bolts.

- Cleaning Cloth: Wipes down the plexiglass to remove dust and fingerprints.

Required Skill Level and Time Commitment

Skill Level: Intermediate

Time Required: 2-3 hours

Steps:

- Measure and Cut Plexiglass: 30-45 minutes

- Prepare the Frame: 20-30 minutes

- Drill Holes in Plexiglass: 15-20 minutes

- Attach Plexiglass to Frame: 30-45 minutes

- Seal Edges: 20-30 minutes

Detailed Installation Steps

Measure the Area:

- Use a tape measure to get the exact dimensions of the space where the plexiglass will go.

- Write down the measurements.

Cut the Plexiglass:

- Place the plexiglass sheet on a flat surface.

- Mark the measurements on the plexiglass using a marker.

- Use a ruler to draw straight lines.

- Score along the lines with a utility knife.

- Snap the plexiglass along the scored lines.

Smooth the Edges:

- Use sandpaper to smooth any rough edges.

- Wipe off any dust with a cloth.

Drill Holes (if needed):

- Mark where you need holes.

- Place a piece of wood under the plexiglass to prevent cracking.

- Use a drill with a bit designed for plastic.

- Drill slowly to avoid cracking.

Clean the Plexiglass:

- Use a soft cloth and mild soap to clean the surface.

- Dry with a lint-free cloth.

Install the Plexiglass:

- Place the plexiglass in the desired location.

- Secure it with screws if needed.

- Use spacers to prevent direct contact with the frame.

Seal the Edges:

- Apply a bead of silicone sealant around the edges.

- Smooth the sealant with a finger or tool.

Final Check:

- Ensure the plexiglass is secure and clean.

- Make any necessary adjustments.

Helpful Tips and Tricks

Measure the area twice before cutting the plexiglass. Use a fine-tooth saw blade for smooth edges. Sand edges with fine-grit sandpaper to avoid sharp corners. Drill holes slowly to prevent cracking. Use a soft cloth to clean plexiglass, avoiding abrasive cleaners. Apply a thin bead of silicone sealant around edges for a secure fit.

Common mistakes include cutting without proper measurements, using the wrong saw blade, and applying too much pressure when drilling. Avoid using ammonia-based cleaners, which can damage the surface.

For alternatives, consider using polycarbonate sheets, which are more impact-resistant. Instead of a saw, a scoring knife can be used for thinner sheets. For sealing, weatherstripping tape can be an alternative to silicone sealant.

Estimating the Project Cost

Plexiglass Sheet: $50-$100 depending on size and thickness.

Measuring Tape: $10.

Marker: $2.

Safety Glasses: $5.

Gloves: $5.

Utility Knife: $10.

Straight Edge: $5.

Drill: $40 (if you don't have one).

Drill Bits: $10.

Screws: $5.

Screwdriver: $5.

Sandpaper: $3.

Cleaning Supplies: $5.

Total Cost: $155-$205.

Budget-Friendly Alternatives:

Plexiglass Sheet: Look for off-cuts or smaller pieces at hardware stores, $30-$50.

Drill: Borrow from a friend or rent, $0-$10.

Screws: Use any you already have, $0.

Total Cost with Alternatives: $105-$145.

Different Ways to Customize

Alternative Materials: Instead of plexiglass, consider using tempered glass for a more durable option. Acrylic sheets can also be a good substitute, offering similar transparency but with different properties.

Colors: Plexiglass comes in various colors. Choose tinted plexiglass for a unique look or frosted plexiglass for added privacy. Colored acrylic sheets can add a vibrant touch to your project.

Styles: For a modern look, use frameless installation techniques. If you prefer a rustic style, consider using wooden frames around the plexiglass. Metal frames can give an industrial feel.

Edge Finishing: Smooth the edges with sandpaper for a clean look. For a decorative touch, use router bits to create beveled or rounded edges.

Mounting Options: Use standoff screws for a floating effect. Adhesive strips can provide a seamless look without visible hardware. Hinges can turn your plexiglass into a functional door or window.

Protective Coatings: Apply UV-resistant coatings to prevent yellowing over time. Anti-scratch coatings can keep the surface looking new longer.

Thickness: Choose thicker plexiglass for added strength. Thinner sheets can be used for lightweight projects or where flexibility is needed.

Patterns: Opt for etched designs or laser-cut patterns to add a custom touch. Printed plexiglass can feature images or designs directly on the surface.

Lighting: Integrate LED strips around the edges for a glowing effect. Backlighting can make the plexiglass stand out, especially in darker settings.

Combining Materials: Mix plexiglass with wood, metal, or fabric for a multi-textured look. Combining different materials can create a unique and personalized project.

Eco-Friendly Tips for Your Project

Materials Needed:

- Plexiglass Sheet: Choose recycled or reclaimed plexiglass if possible.

- Measuring Tape: Use a durable, long-lasting one.

- Marker: Opt for a refillable marker.

- Saw: A hand saw or a jigsaw with a fine blade.

- Drill: A hand drill or a power drill with a low energy consumption.

- Screws: Reuse screws from previous projects or buy ones made from recycled materials.

- Screwdriver: Manual or electric with rechargeable batteries.

- Sandpaper: Use eco-friendly sandpaper made from recycled materials.

- Cleaning Cloth: A reusable microfiber cloth.

Steps:

Measure the Area: Use the measuring tape to measure the area where the plexiglass will be installed. Mark the dimensions on the plexiglass sheet with the refillable marker.

Cut the Plexiglass: Secure the plexiglass sheet on a stable surface. Use the hand saw or jigsaw to cut along the marked lines. Cutting slowly reduces waste and ensures a cleaner cut.

Smooth the Edges: Sand the cut edges with eco-friendly sandpaper until smooth. This step prevents injuries and ensures a better fit.

Drill Holes: Mark the spots where screws will go. Use the hand drill or a low-energy power drill to make holes. Drilling slowly helps avoid cracking the plexiglass.

Clean the Plexiglass: Wipe the plexiglass with a reusable microfiber cloth to remove dust and debris.

Install the Plexiglass: Align the plexiglass with the pre-drilled holes. Insert the recycled screws and tighten them using a manual or rechargeable screwdriver.

Final Touches: Ensure the plexiglass is securely in place. Clean any fingerprints or smudges with the microfiber cloth.

Using recycled or reclaimed materials, along with tools that have a low environmental impact, makes this project more sustainable.

Your Plexiglass Project Awaits

You've got all the tools and know-how to install plexiglass like a pro. Just remember to measure twice, cut once. Keep your workspace clean and organized to avoid mishaps. Safety first—wear those goggles and gloves. When drilling, go slow to prevent cracks. Use the right adhesive for a strong bond. If you mess up, don't sweat it. Mistakes happen, and they're part of the learning process. With patience and practice, you'll get better. Now, go ahead and tackle that project. Whether it's a window, a display case, or a DIY greenhouse, you've got this. Enjoy the satisfaction of a job well done. Happy building!

How do I measure for plexiglass installation?

Measure the height and width of the area where you want to install the plexiglass. Use a tape measure for accuracy. Write down the measurements and double-check them.

What tools do I need to install plexiglass?

You’ll need a tape measure, drill, screws, screwdriver, saw (if cutting is required), sandpaper, and safety goggles. Having a level helps too.

How do I cut plexiglass to size?

Mark the cutting line with a marker and use a saw with fine teeth. Cut slowly to avoid cracking. Sand the edges with sandpaper to smooth them out.

Can I drill holes in plexiglass?

Yes, you can drill holes. Use a drill bit designed for plastic. Drill slowly and apply light pressure to prevent cracking.

How do I secure plexiglass in place?

Use screws and brackets to secure the plexiglass. Drill pilot holes first to make it easier. Tighten the screws just enough to hold the plexiglass without cracking it.

How do I clean plexiglass after installation?

Use a soft cloth and mild soap mixed with water. Avoid using ammonia-based cleaners as they can damage the surface. Dry with a lint-free cloth.

Can I paint plexiglass?

Yes, you can paint plexiglass. Use acrylic paint and a primer designed for plastic. Apply thin, even coats and let each coat dry before adding another.